RF Absorbers selection guide. Choose right ensures smooth design-to-build transitions.

EV | Telecom | New Energy | Data Centre | Robotics

Introduction to RF Absorbers for Signal Integrity

In modern high-frequency electronics, managing stray signals is just as important as shielding them. RF absorbers play a critical role by converting electromagnetic energy into heat, thereby reducing reflections and interference within an enclosure. By using high-quality RFI absorbers, engineers can suppress unwanted cavity resonances and ensure that sensitive components perform according to their design specifications.

Categorizing Different Types of RF Absorbers

When selecting RFI absorbers, it is essential to categorize them by their physical form and the frequency range they are designed to target. Not all RF absorbers are created equal; some are optimized for narrow-band military applications, while others provide broad-band suppression for commercial telecommunications.

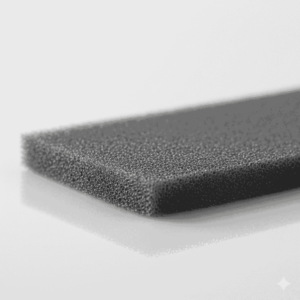

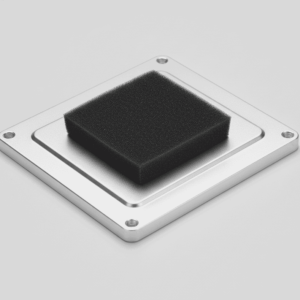

- Foam-Based Microwave Absorbers: These lightweight RFI absorbers are typically carbon-filled and used in anechoic chambers or large enclosures to dampen wide-frequency reflections.

- Elastomeric RFI Absorbing Sheets: Made from silicone or urethane, these thin RF absorbers are loaded with magnetic fillers. They are ideal for sticking directly onto noisy ICs or the inside of mobile device housings.

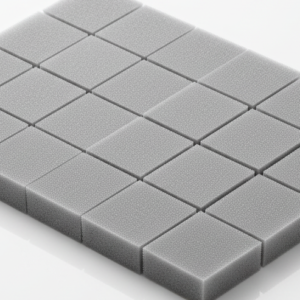

- Pyramidal RFI Absorbers: Recognizable by their spiked shape, these are used when maximum surface area is needed to trap and dissipate radio waves across a vast spectrum.

Why Radio Frequency Attenuation Performance Varies

The effectiveness of RFI absorbers is measured by their insertion loss and reflectivity. Depending on the material thickness and filler concentration, RFI absorbers can be tuned to specific “resonant” frequencies or designed for “broadband” use. Understanding these performance metrics is key to preventing signal degradation in $5G$, radar, and satellite systems.

Application of Advanced RF Absorbers in Modern Tech

To ensure your project meets rigorous testing standards, you should cross-reference your material choice with industry benchmarks like the IEEE Standard for Measuring Shielding Effectiveness. Properly implemented RFI absorbers are the final step in achieving a silent, interference-free electronic environment. Whether you are working on automotive radar or high-speed networking, the right RF absorbers make the difference between a failed test and a market-ready product.