Adhesives for Electronics & Automotive

EV | Telecom | New Energy | Data Centre | Robotics

High-Performance Adhesives for Electronics & Automotive Applications

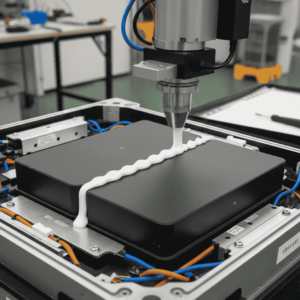

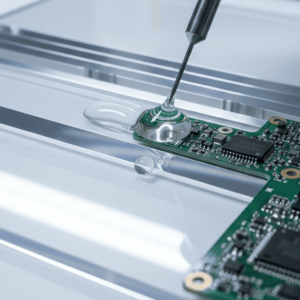

In the modern manufacturing landscape, the demand for reliable bonding solutions has never been higher. Our specialized Adhesives for Electronics & Automotive sectors are engineered to meet the rigorous challenges of thermal management, electrical grounding, and structural integrity. Unlike standard industrial glues, these materials are formulated to survive harsh environments, from the high-heat engine bays of electric vehicles to the delicate circuitry of consumer handhelds. By selecting the correct Adhesives for Electronics & Automotive, engineers can ensure long-term reliability and peak performance.

Categorizing Specialized Adhesives for Electronics & Automotive

To help you find the right solution for your specific project, we categorize our inventory based on functional performance and chemical composition:

- Thermally Conductive Options: These Adhesives are designed to dissipate heat away from sensitive components like CPUs or power transistors. They are vital for preventing thermal throttling and extending the life of hardware.

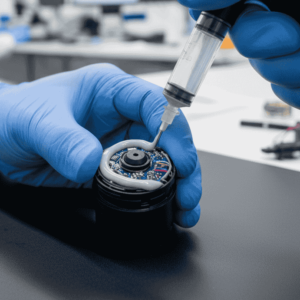

- Electrically Conductive Bonding: Used primarily for EMI shielding and grounding, these Adhesives contain silver or nickel fillers. They provide a low-resistance path for electricity, making them ideal for radar systems and communication modules.

- Structural and Encapsulating Resins: For components exposed to high vibration, these Adhesives provide the mechanical strength needed to keep parts in place while protecting them from moisture and dust.

Why Material Selection Matters in Electronics Design

When designing Adhesives for Electronics & Automotive use, one must consider thermal expansion. Vehicles undergo extreme temperature swings; therefore, the adhesive must be flexible enough to expand and contract without cracking the PCB. Our range of Adhesives for Electronics & Automotive includes silicone-based formulas that offer excellent stress relief and epoxy-based versions for high-strength requirements.

Industry Standards and Compliance

Every product in our Adhesives line is tested against international standards. Whether you are looking for UL-94 V-0 flame retardancy or compliance with IPC-CA-821 for electrical grade epoxies, our materials provide the data-backed assurance your project requires. Using the right Adhesives ensures that your devices not only pass initial quality checks but remain functional for years in the field.