SMP5110 Silane modified polyether adhesive for industrial use

Product Highlights of Silane modified polyether adhesive

- Environmentally friendly products: fast curing, low VOC, non-toxic and odor-less, no pollution or corrosion to the substrate.

- Surface coating: After the surface is dry, it can be sprayed with paint for coloring.

- Good operability: single component, easy to operate,

within the temperature range of 4 ℃~40 ℃ - It has good extrusiveness and can be directly applied

by extruding with a glue gun. - Excellent weather resistance, aging resistance, dielectric and

mechanical properties. - Excellent adhesion: to metals, glass, ceramics, wood, PVC, PC, PA

- The material has excellent adhesion.

Product Applications of Silane modified polyether adhesive

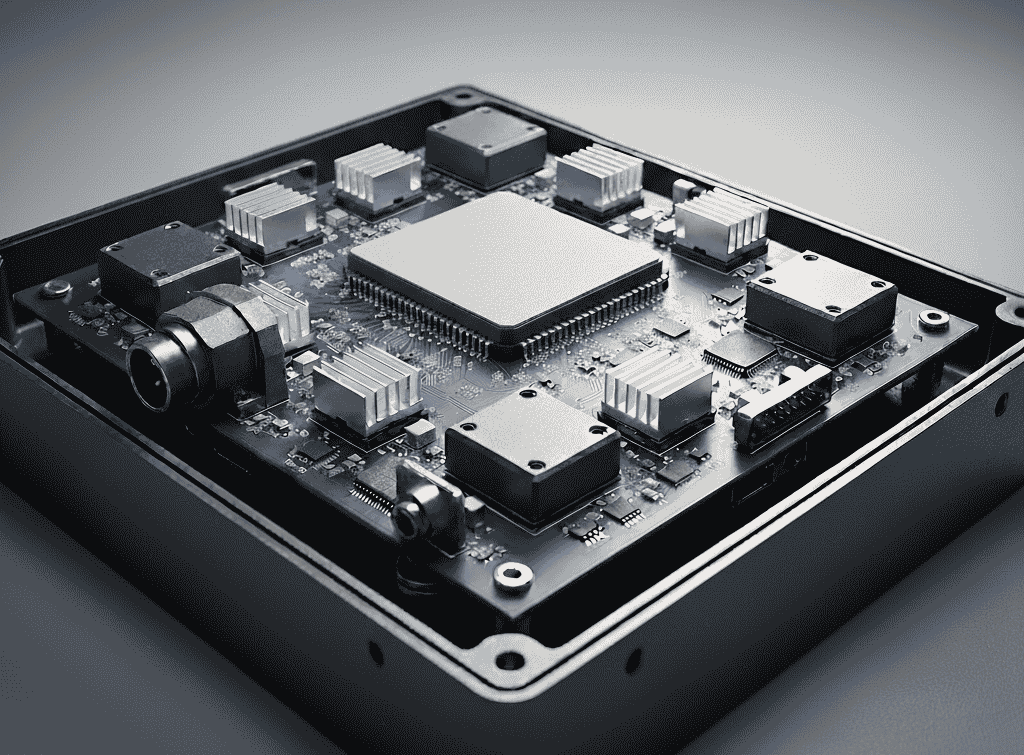

- Adhesive and sealing for vehicle windshields

- Adhesive and sealant for vehicle side windows

- Adhesive and sealant for vehicle lightings

SPECIFICATIONS TABLE

Recommended

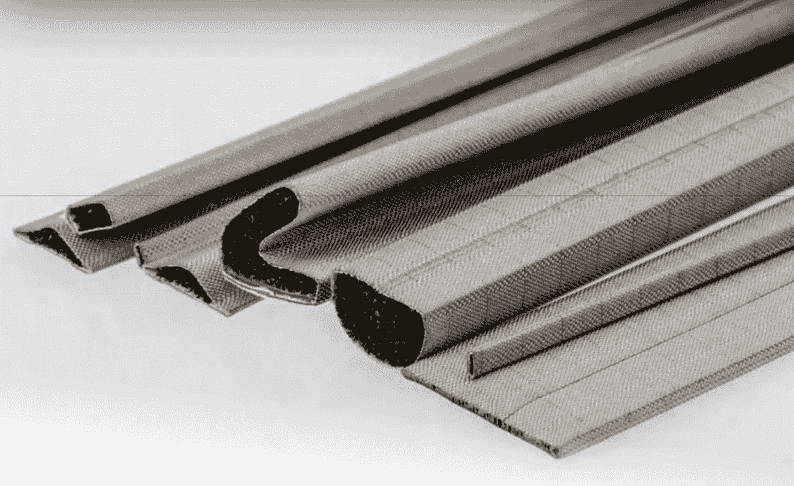

Fabric-over-Foam EMI Gasket OEF-series

RF Absorber EMI-Thermal Hybrid HW9000-series

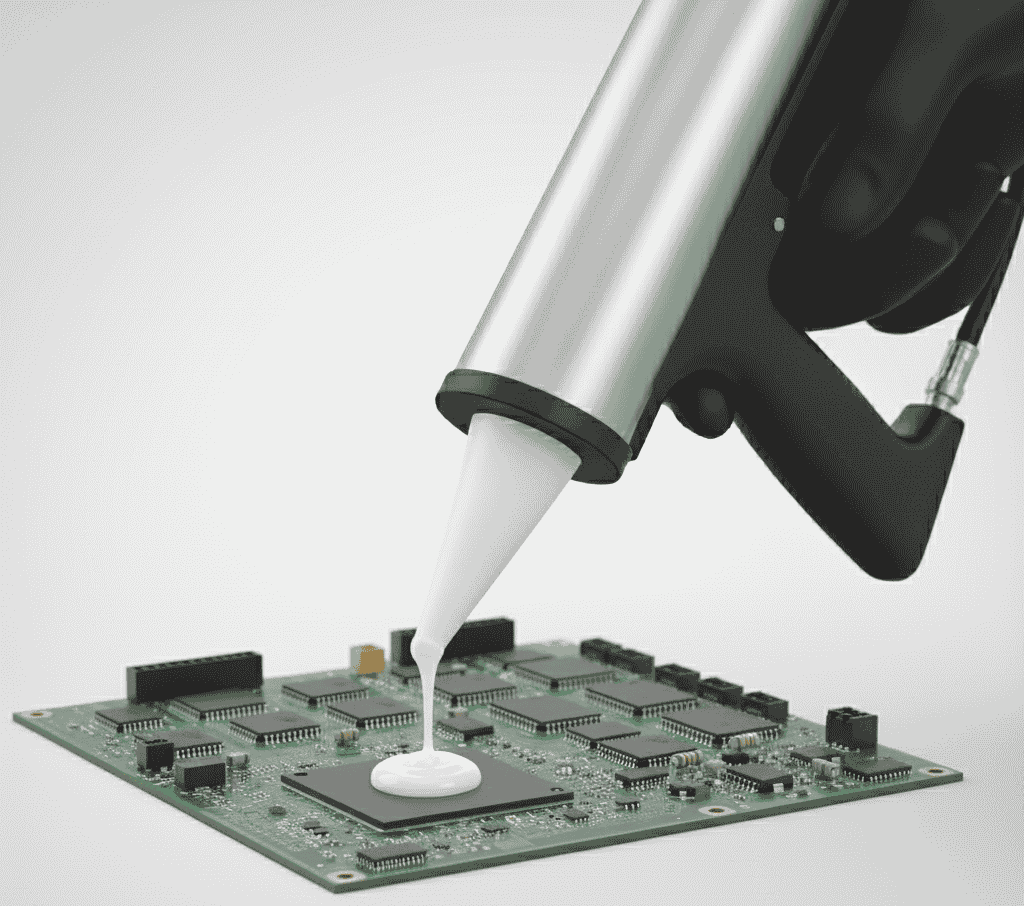

Silicone-Free Thermal Conductive Gel NFG-series

| Item | Test parameters | Design parameters | Test method |

| color | white | white | – |

| Curing method | moisture curing | moisture curing | – |

| Working temperature (° C) | -40~+90 | -40~+90 | – |

| 120(Within 1 hour) | 120(Within 1 hour) | – | |

| Dry time (min) | 8~40 | 8 | GB/T 13477-2002 |

| Curing rate (mm/24h) | 4~5 | 4 | – |

| Density (g/cm ³) | 1.40~1.60 | 1.40 | GB/T 13477-2002 |

| Hardness (Shore A) | 35~55 | 55 | GB/T 531-2009 |

| Tensile strength (MPa) | ≥2.5 | ≥2.5 | GB/T 528-2009 |

| Tensile elongation at break (%) | ≥200 | ≥200 | GB/T 528-2009 |

| Shear strength (MPa) | ≥2.0 | ≥2.0 | GB/T7124-2008 |

| Tear strength (N/mm) | ≥8 | ≥8 | GB/T 529-2008 |

| Volume resistivity (Ω. cm-1) | ≥1×109 | ≥1×109 | GB/T 1692-2008 |

| Storage period (month) | 6 | 6 | – |

Usage Instructions

Before using this product, operators should thoroughly read the safety information provided.

Ensure the application surface is clean, dry, and free from dust or debris.

Application can be carried out using either a manual or pneumatic glue gun.

Adequate ventilation must be maintained during both application and curing.

To achieve optimal bonding performance, conduct a bonding test before large-scale application. Additionally, perform regular peel tests throughout the construction process to verify bonding effectiveness.

Safety Instructions

This product is non-toxic once fully cured. However, avoid contact with the eyes before it cures. In case of eye contact, rinse immediately with plenty of water and seek medical attention.

Keep uncured product out of reach of children.

Packaging

Net volume: 300 ml per unit.

Storage and Shelf Life

Store in a cool, dry place at temperatures below 27°C.

Shelf life: 6 months from the production date.

Technical Overview & Compliance

The Silane Modified Polyether Adhesive combines the best attributes of silicones and polyurethanes. This hybrid chemistry offers the high strength and paintability of polyurethanes with the UV resistance and long-term durability of silicones. It is uniquely formulated to be isocyanate-free and low-VOC, providing a safer working environment without sacrificing bond integrity on diverse substrates like galvanized steel, aluminum, and engineering plastics.

To ensure the highest reliability in structural and sealing applications, our MS Polymers are tested and rated according to the ASTM C920 Standard Specification for Elastomeric Joint Sealants. This compliance ensures that the Silane Modified Polyether Adhesive maintains its movement capability and adhesion through rigorous thermal cycling and environmental exposure. By adhering to these industry-standard benchmarks, we guarantee a robust, non-corrosive bonding solution for the automotive, marine, and construction industries.