PU334UV single component UV cured adhesive sealant

PU334UV is a one-component, UV-curable adhesive sealant formulated with polyurethane acrylic resin. It offers excellent chemical resistance, surface hardness, flexibility, and moisture resistance.

Curing is achieved under ultraviolet light, and the adhesive layer fluoresces under UV exposure, allowing for easy inspection. The product is compatible with selective coating equipment for precise application.

Applications of UV cured adhesive sealant

The adhesive can be applied using standard selective coating systems or manual spraying equipment. Ensure adequate ventilation during application to safely remove vapors and mist from the operator’s environment.

Product Highlights of UV cured adhesive sealant

- Suitable for bonding and sealing various substrates

- UV curing

- Under ultraviolet light, the material will exhibit fluorescence, making it easier to detect

- Excellent chemical and physical properties

SPECIFICATIONS TABLE

Recommended

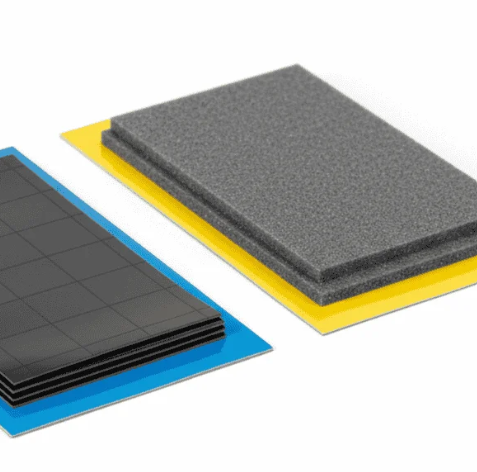

Thermal Pad TFP-H Series 6.0 ~ 15.0 W/mK

Electrically Conductive Sponge – Foam FEF-series

RF Absorber Hybrid Gel | SF Series

| Item | Unit | PU334UV | Testing method |

| appearance | – | Colorless translucent fluid | visual estimation |

| Solvent content | – | No non reactive solvents | – |

| Type of resin | – | Polyurethane acrylic resin | – |

| density | g/cm³ | 1.10±0.05 | GB/T 533-2008 |

| viscosity | cps | 10,000~20,000 | GB/T 2794-2013, 10 rpm |

| Recommended light source | – | LED 365nm, UVA | – |

| Recommended UV curing intensity | mW/cm² | 500 | – |

| Recommended UV curing time | s | 10 | – |

| Curing depth | um | >120 | – |

| volume resistivity | ohm.cm | ≥1X1014 | GB/T 1410-2006 |

| breakdown voltage | kV/mm | ≥25 | GB/T 1408.1-2006 |

| hardness | Shore-D | 75±5 | GB/T 531.1-2008 |

| shear strength | MPa | ≥8(PC-PC) | GB/T 7124-2008 |

Packaging

Packaging can be customized based on customer requirements, including bulk containers and large barrels.

Storage and Shelf Life

- As the product is photosensitive, avoid exposure to direct sunlight and full-spectrum fluorescent lighting.

- Improper storage conditions may negatively impact the product’s performance and curing results.

- Recommended storage temperature: -20°C to maximize shelf life.

Instructions for Use

• Surface Preparation

Before application, thoroughly clean the bonding area using gauze or suitable tools to remove dust, loose debris, oil, and moisture.

If rust is present, remove it with a wire brush, then wipe the surface with acetone or alcohol for optimal adhesion.

Precautions

- Dispose of the sealant in accordance with local environmental regulations.

- Use only in well-ventilated areas to prevent inhalation of vapors or mist.

- Do not use wet application techniques. Avoid the use of solvents, water, cleaning agents, or soap-based solutions.

- Prevent contact with skin and eyes.

Pre-Test Recommendation

To avoid issues during application, it is recommended to perform preliminary testing using all intended materials. This helps in selecting the most suitable adhesive and determining the ideal surface preparation method to achieve optimal bonding performance.

Technical Overview & Compliance of UV cured adhesive sealant

Our UV Cured Adhesive Sealant is a specialized “cure-on-demand” resin that transitions from liquid to a robust solid in seconds when exposed to specific wavelengths of ultraviolet light. This rapid polymerization allows for precise alignment of components before fixing them in place, making it ideal for camera module assembly, fiber optic terminations, and sensor encapsulation. These sealants are formulated to offer low shrinkage and high optical clarity, ensuring that sensitive alignments remain stable throughout the life of the product.

To ensure these adhesives meet the strict requirements of high-tech manufacturing, they are tested in accordance with ISO 10993 for Biological Evaluation of Medical Devices (where applicable) or specific electronic reliability standards. Furthermore, our UV adhesives are designed to meet the Telcordia GR-1221-CORE reliability requirements for passive optical components, ensuring they can withstand extreme humidity and thermal cycling without delamination or loss of seal integrity. This makes our UV Cured Adhesive Sealant a trusted choice for the most demanding telecommunications and medical electronics applications.