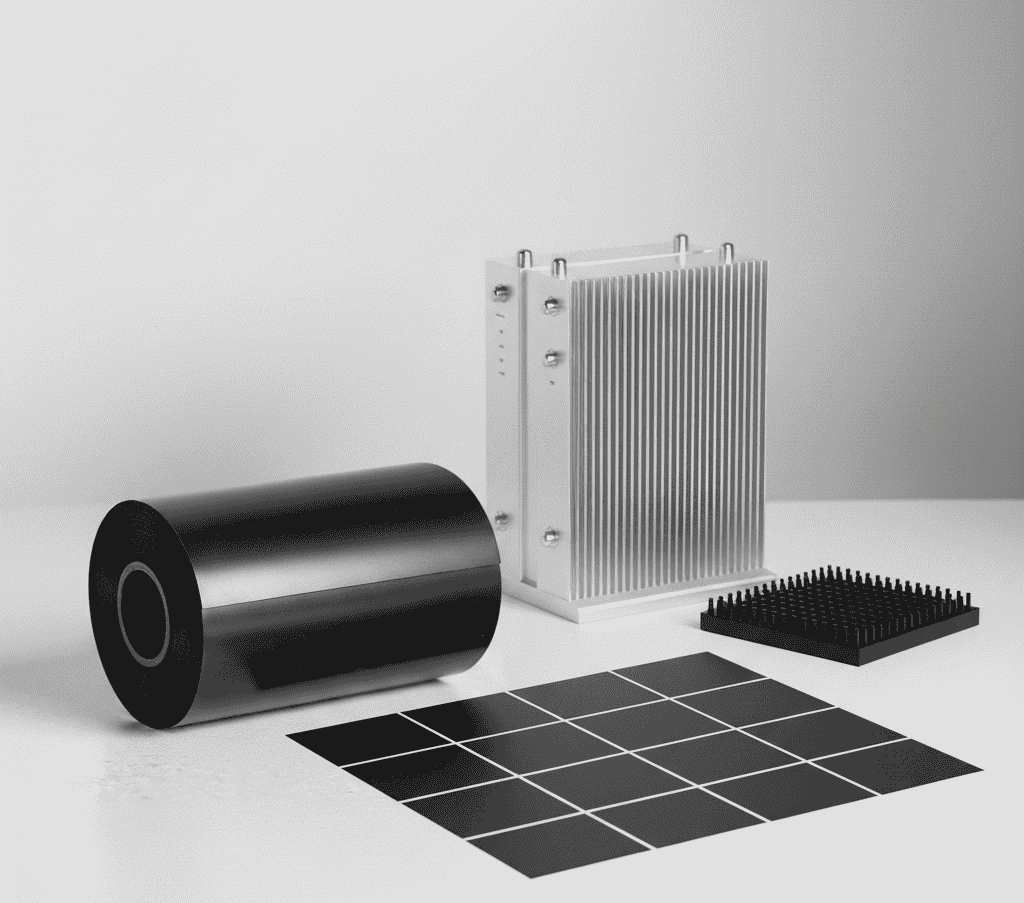

GRF-series | Thermally Conductive Graphite Film

Product Highlights

- High thermal conductivity, better than natural graphite

- Excellent temperature resistance, no volatile matter, no pollution to products

- Product shape can be customized according to customer drawings

Applications

- Smartphone

- Tablet PC

- Vapors, radiators

- Electromagnetic shielding

Storage Condition

- Sealed storage

- Storage temperature is 20~35°C, moisture-proof, avoid direct sunlight

- (After adhesive layer applied) the shelf life is 6 months

GBA’S GRF series is a synthetic graphite material known for its ultra-high thermal conductivity in the planar direction. The material features a regular carbon hexagonal layered structure in the horizontal direction, enabling thermal conductivity of up to 1,500 W/m-K.

This exceptional performance makes it ideal for high-efficiency heat dissipation applications. Additionally, the material can be equipped with an adhesive on one side, allowing for easy handling and installation.

Our Thermally Conductive Graphite Film provides exceptional in-plane heat spreading, making it an essential solution for ultra-thin electronics and mobile devices. To verify the performance of these carbon-based materials, we utilize testing methodologies aligned with the ASTM D5470 standard. This ensures that every Thermally Conductive Graphite Film we manufacture delivers the precise thermal management and reliability required for advanced aerospace and telecommunications applications.

SPECIFICATIONS TABLE

| Item | GRF150S | GRF100S | Test Method | ||||||||

| Physical Property | |||||||||||

| Colour | Black | Black | Visual | ||||||||

| Material | Synthetic Graphite | Synthetic Graphite | – | ||||||||

| Operating Temperature (°C) | -55~+400 | -55~+400 | – | ||||||||

| Hardness | 90 Shore A | 90 ShoreA | ASTM D2240 | ||||||||

| Thickness (mm) | 0.012 | 0.017 | 0.025 | 0.04 | 0.05 | 0.085 | 0.09 | 0.1 | 0.11 | 0.12 | ASTM D374 |

| Raw Material Width (mm) | 100 | 130 | 140 | 140 | 140 | 100 | 130 | 140 | 140 | 140 | – |

| Density (g/cm³) | 2.17 | 2.13 | 2.1 | 1.8 | 1.7 | 2.17 | 2.13 | 2.1 | 1.8 | 1.7 | ASTM D792 |

| Tensile Strength (PSI) | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | ASTM D412 |

| Fold Durability (R5/180°) | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | – |

| Electrical Performance | |||||||||||

| Volume Resistivity (ohm-cm) | 11×10-3 | 11×10-3 | ASTM D257 | ||||||||

| Conductivity (S/cm) | 19000 | 20000 | – | ||||||||

| Breakdown Voltage | >4000AC | >4000AC | ASTM D149 | ||||||||

| Thermal Performance | |||||||||||

| X-Y Axis Thermal Conductivity (W/m·K) | 1800 | 1700 | 1500 | 1300 | 1100 | 1800 | 1700 | 1500 | 1300 | 1100 | Hot Disk |

| Z Axis Thermal Conductivity (W/m·K) | 15 | 10 | ASTM D5470 | ||||||||

| Specific Heat Capacity (J/(Kg·K)) | 710 | 710 | ASTM D2766 | ||||||||

| RoHS | Yes | Yes | – | ||||||||