Thermal Pad TFP-H Series | 6.0 ~ 15.0 W/mK

Other Thermal conductivities selections

1.0 – 1.5 W/mK

2.2 – 3.0 W/mK

3.5 – 5.1 W/mK

Product Highlights of Thermal Pad TFP H Series (6.0 ~ 15.0 W/mK)

- Thermal conductivity 6.0 ~ 15.0 W/mK

- Self adhesion

- UL94 V-0 flame retardant grade

- Thickness range: 0.003 inch (0.07mm) -0.400 inch (10.0mm)

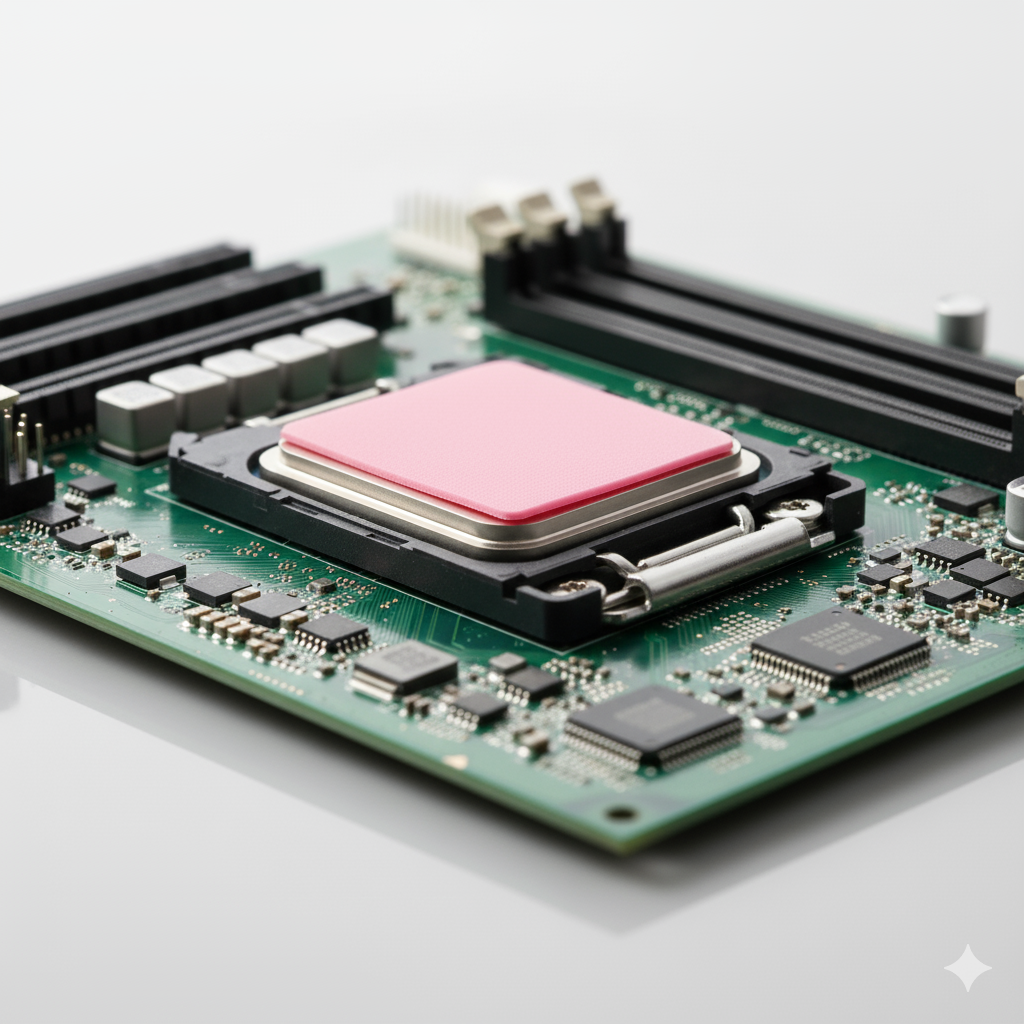

Application Examples of of Thermal Pad TFP H Series (6.0 ~ 15.0 W/mK)

- Desktop computer, laptop and server

- LED lighting equipment

- Automotive electronics

- LCD and PDP flat display

- Automotive electrical modules, battery heat dissipation

The TFP series of thermal pads, with thermal conductivity ranging from 6 to 15 W/mK, deliver high performance. Thanks to a special formulation, these pads offer excellent thermal efficiency while remaining easy to handle. The material’s natural tackiness ensures optimal contact with the application surface, effectively reducing thermal resistance and enhancing heat transfer.

For added convenience during use and rework, a non-sticky “dry surface” is created on one side of the pad through a unique process. This non-tacky side allows for easy removal from IC chips, PCBs, or other components without causing damage. The tacky side is typically applied to heat sinks, cold plates, or housings for efficient heat dissipation, ensuring a secure fit for long-lasting performance.

Industry-Standard Thermal Validation of Thermal Pad TFP series L

To ensure the accuracy of our Thermal Pad 1.0-1.5w/mK ratings, we verify all TFP series materials using the ASTM D5470 standard. This ensures that the thermal impedance and conductivity data we provide are measured through the industry-recognized steady-state method, giving you total confidence in your heat dissipation calculations

SPECIFICATIONS TABLE

| Part Numbers | TFP6055 | TFP6025RB | TFP8050 | TFP8050UV | TFP8005 | TFP8025 | TFPX055 | TFPX255 | TFPX560 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Parameters | Unit of Measure | |||||||||

| Colour | – | Grey | Burgundy | Grey | Light Grey | Light Grey | Light Grey | Grey | Grey | Grey |

| Thickness | mm | 0.3~10 | 0.3~10 | 0.3~10 | 0.3~10 | 0.5~10 | 0.3~10 | 0.3~10 | 0.3~10 | 0.5~10 |

| Thermal Conductivity | W/m·K | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 12 | 15 |

| Thermal Resistance @1mm,20psi | ℃·in²/W | 0.26 | 0.24 | 0.25 | 0.25 | 0.2 | 0.22 | 0.21 | 0.19 | 0.17 |

| ℃·cm²/W | 1.68 | 1.55 | 1.61 | 1.61 | 1.29 | 1.03 | 1.48 | 1.41 | 1.29 | |

| Hardness | Shore00 | 55 | 25 | 50 | 50 | 5 | 25 | 55 | 55 | 60 |

| Flammability Rating | V0 | V0 | V0 | V0 | V0 | V0 | V0 | V0 | V0 | |

| Breakdown Voltage | kV(@1mm) | >9.0 | >9.0 | >8.0 | >8.0 | >6 | >8 | >6 | >6 | >6 |

| Volume Resistivity | Ω ·cm | ≥1.0×10¹² | ≥1.0×10¹² | ≥1.0×10¹¹ | ≥1.0×10¹¹ | ≥1.0×10¹¹ | ≥1.0×10¹¹ | ≥1.0×10⁹ | ≥1.0×10⁹ | ≥1.0×10⁹ |

| Density | g/cm³ | 3.1 | 3.15 | 3.07 | 3.3 | 3.3 | 3.3 | 3.35 | 3.17 | 3.27 |

| Tensile Strength | psi | 52 | 52 | 40 | 40 | 20 | 25 | 30 | 30 | 30 |

| Elongation | % | 50 | 50 | 45 | 45 | 40 | 40 | 25 | 25 | 25 |

| Compression Ratio (%, at given pressure) | 10psi | 11 | 15 | 8 | 8 | 20 | 15 | 12 | 8 | 8 |

| 50psi | 30 | 38 | 26 | 26 | 45 | 35 | 25 | 23 | 22 | |

| 100psi | 48 | 60 | 42 | 42 | 80 | 65 | 42 | 39 | 36 | |

| Dielectric Constant | @1MHz | 6.5 | 6.5 | 13.5 | 8.5 | 6.5 | 6.5 | 8.5 | 8.5 | 8.5 |

| Low Volatile Content (D4~D20) | ppm | – | – | <20 | <20 | <20 | <20 | – | <20 | <20 |

| TML(CVCM) | % | ≤0.15(0.04) | ≤0.15(0.04) | ≤0.15(0.05) | ≤0.15(0.05) | ≤0.25(0.08) | ≤0.25(0.08) | ≤0.15(0.08) | ≤0.12(0.05) | ≤0.12(0.05) |

| Operating Temperature | ℃ | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 |

| RoHS | YES | YES | YES | YES | YES | YES | YES | YES | YES |