RF Absorber EMI-Thermal Hybrid HW9000-series

Product Highlights of RF Absorber EMI-Thermal Hybrid:

- Soft and resilient

- Thickness range: 0.5 – 5mm, tolerance in 10% of the thickness

- Thermally conductive and RF absorbing, two functions in one material

- Naturally tacky, PSA is not necessary

- Flame rating: UL94 V-0

Product application of RF Absorber EMI-Thermal Hybrid:

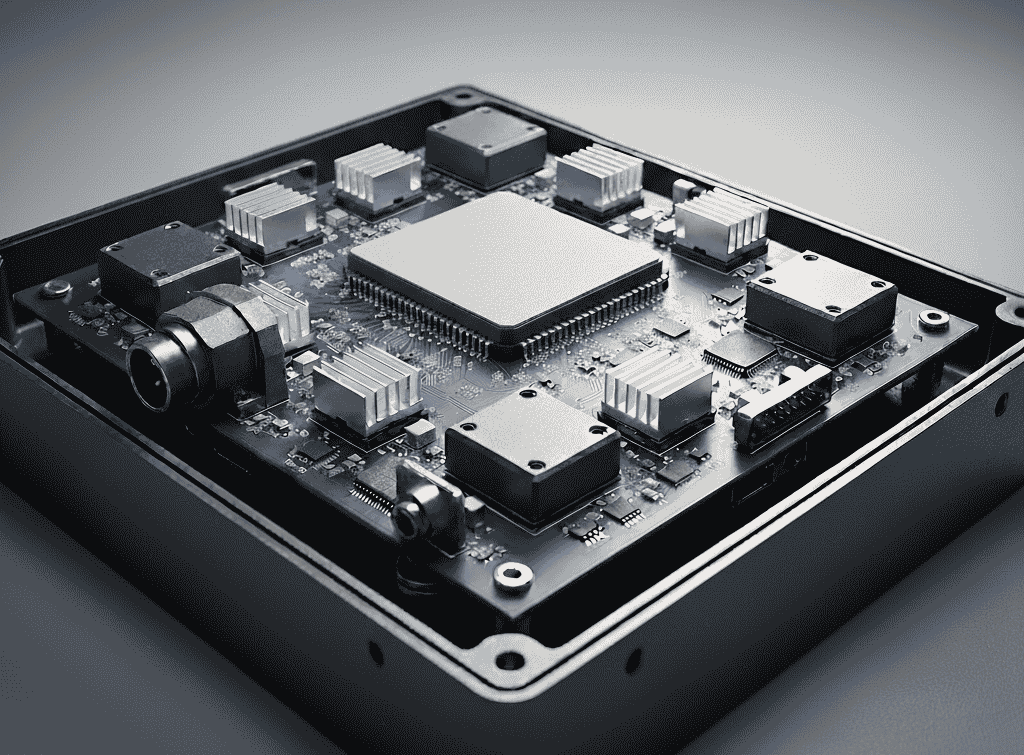

- Automotive electronics

- Medical instrument

- Radar

- 5G antenna

- Communication equipment

The HW9000-series thermally conductive absorbers have dual functions of wave absorption and thermal conduction. They are composite materials made of polymer and various wave absorbing fillers and additives. The product can achieve low interface thermal resistance and absorb electromagnetic waves at low pressure and has good electrical insulation and environmental stability.

HW9000-series, like the use of thermal pads, is placed between the heat source/electromagnetic wave radiation source and the heat sink to conduct heat conduction while absorbing electromagnetic waves. This product is especially suitable for the application of optical transceiver in the telecommunication industry.

Technical Overview & Compliance

The RF Absorber EMI-Thermal Hybrid is a cutting-edge composite engineered for high-density power electronics where heat and noise occur simultaneously. By combining thermally conductive ceramic fillers with microwave-absorbing magnetic particles in a soft silicone matrix, these materials eliminate the need for separate thermal pads and EMI shields. This reduces the thermal resistance between the component and the heat sink while suppressing high-frequency resonances that can degrade signal integrity.

To guarantee the reliability of these multi-functional materials in critical systems, they are tested under the ASTM E595 Standard Test Method for Outgassing. This compliance is essential for aerospace, satellite, and high-vacuum applications, ensuring that the RF Absorber EMI-Thermal Hybrid does not release volatile condensable materials that could contaminate sensitive optical or electronic sensors during thermal cycling.

SPECIFICATIONS TABLE

| Parameters | Test Method | Units of Measure | HW9010 | HW9010AD | HW9030 | HW9040 | HW9060 | |||||

| Color | – | – | Gray | Gray | Gray | Gray | Gray | |||||

| Substrate | – | – | Silicone | Silicone | Silicone | Silicone | Silicone | |||||

| Filler | – | – | Carbonyl Iron & Oxidized Aluminum | |||||||||

| Hardness | ASTM 2240 | Shore OO | 45+/-5 | 55 | 50+/-5 | 50+/-5 | 55+/-5 | |||||

| Density | ASTM D792 | g/cm³ | 4.0 | 4.2 | 3.6 | 4.2 | 3.8 | |||||

| Operating Temperature | ASTM D1329 | ℃ | -45~+200 | -45~+200 | -45~+200 | -45~+200 | -45~+200 | |||||

| Volume Resistance | MIL-DTL-83528C | Ohm-cm | ≥10⁹ | ≥10⁹ | ≥10⁹ | ≥10⁹ | ≥10⁹ | |||||

| Breakdown Voltage | ASTM D149 | KV | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | |||||

| Flammability | UL94 | – | V-0 | V-0 | V-0 | V-0 | V-O | |||||

| Thermal Conductivity | ASTM D5470 | W/m·K | 1.8 | 1.5 | 3.2 | 4.0 | 6.0±0.6 | |||||

| Thermal Resistance vs. Pressure | Compression Rate | Compression Rate % | Thermal Resistance ℃·in²/w | Compression Rate % | Thermal Resistance ℃·in²/w | Compression Rate % | Thermal Resistance ℃·in²/w | Compression Rate % | Thermal Resistance ℃·in²/w | Compression Rate % | Thermal Resistance ℃·in²/w | |

| @20 PSI | @20 PSI | 0.89 | @20 PSI | 1.16 | @20 PSI | 0.4 | @20 PSI | 0.37 | @20 PSI | 0.28 | ||

Performance Data