PU7052 Two Component Polyurethane Structural Adhesive

Product Highlights of Polyurethane Structural Adhesive:

- High strength

- Aging resistance

- Vibration fatigue resistance

- Low temperature corrosion resistance

- Low odor, low emissions

- Excellent flame retardant performance

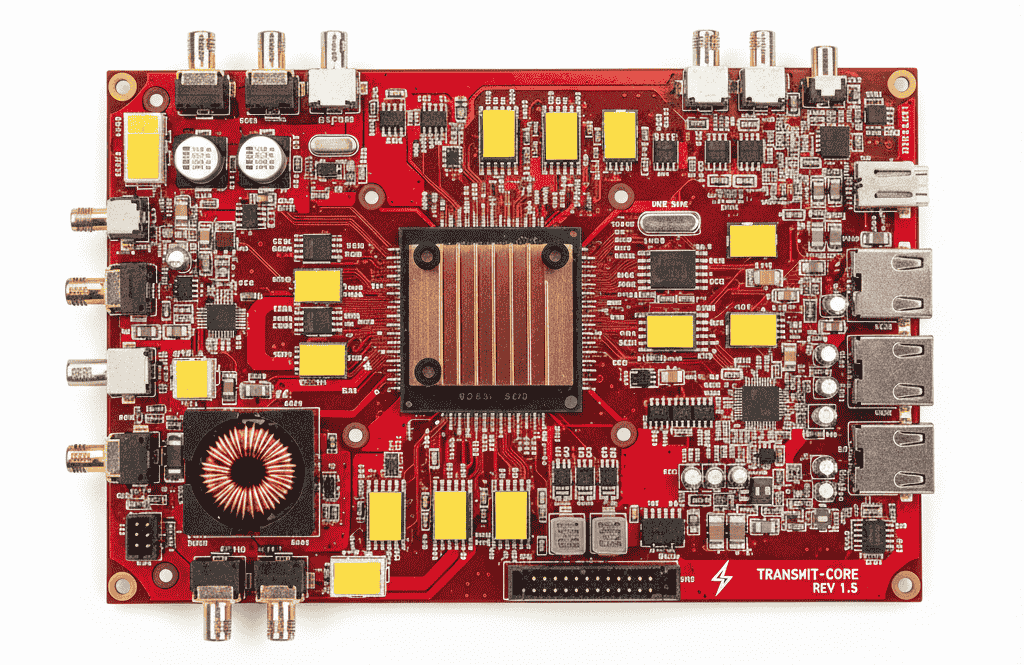

- Suitable for bonding multiple materials

Product Applications:

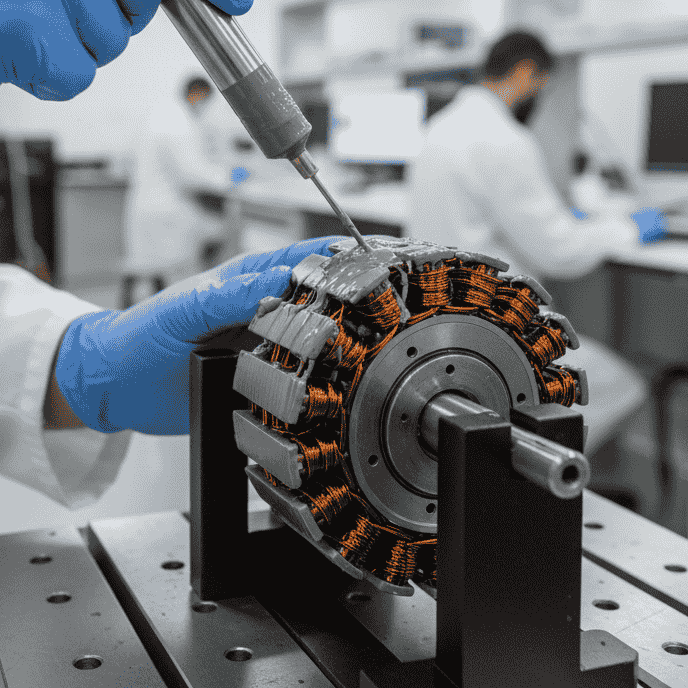

- adhesive between cells in batteries

- Adhesive bonding between two structural modules

- Adhesive and sealant for components

SPECIFICATIONS TABLE PU7052

| Item | Unit | Index | Typical Value | Test Method |

| appearance | / | A: Black paste B: White paste | A: Black paste B: White paste | visual |

| density | g/cm3 | A: 1.40 ± 0.05 B: 1.40 ± 0.05 | A: 1.37 B: 1.39 | GB/T 533-2008 |

| Viscosity | cps | A: 150,000~200,000 B: 150,000~200,000 | A: 170,000 B: 160,000 | GB/T 2794-2013 10 rpm |

| Mixing ratio | v/v | 1:01 | 1:01 | / |

| surface drying time | min | 15–20 | 16 | GB/T 13477.5-2002 |

| hardness | Shore D | 65 ± 5 | 65 | GB/T 531.1-2008 |

| Body tensile strength | MPa | ≥ 8.0 | 10 | GB/T 528-2009 |

| elongation at break | % | ≥ 40 | 70 | GB/T 528-2009 |

| tensile shear strength | MPa | ≥ 15.0 (Al–Al) | 15.7 | GB/T 7124-2008 |

| pull strength | MPa | ≥ 11.5 (Al–Al) | 17 | GB/T 6329-1996 |

Operation and Safety Guidelines

Surface Preparation:

Before applying the adhesive, clean the surface using gauze or appropriate tools to remove dust, loose particles, oil stains, and water marks. If rust is present, remove it with a wire brush, then clean the area using acetone or alcohol.

Primer and Cleaning Agent:

To ensure optimal adhesion, use the appropriate primers and cleaning agents. When applying these materials, make sure the coating is uniform, with no excess buildup or missed areas on the substrate surface.

Mixing:

PU7052, a two-component polyurethane structural adhesive, should be mixed using a static mixing tube.

Application:

Apply the PU7052 adhesive using a pneumatic or electric dispensing gun, or other suitable application equipment, directly at the construction site.

Packaging, storage, and expiration date

We can provide 50 mL, 400 mL, and 600 mL two-component rubber hose packaging or 20 L small buckets and 200 L large buckets packaging according to customer requirements;

It is recommended to store in a cool and dry place for a storage period of 6 months;

Incorrect storage conditions can affect product application and performance after curing.

Packaging, Storage, and Shelf Life

We offer packaging options including 50 mL, 400 mL, and 600 mL two-component cartridges, as well as 20 L pails and 200 L drums, depending on customer requirements.

For best results, store the product in a cool, dry environment. The recommended shelf life is 6 months.

Improper storage conditions may impact the product’s application performance and cured properties.

Technical Overview & Compliance

Our Polyurethane Structural Adhesive is engineered for applications that require a balance of high shear strength and significant elongation. Unlike rigid epoxies, these adhesives remain flexible enough to absorb vibrations and compensate for the differing coefficients of thermal expansion (CTE) in bonded substrates, such as aluminum to carbon fiber or plastics to steel. This makes them indispensable for structural bonding in electric vehicle frames and aerospace interiors where mechanical stress and thermal cycling are constant.

To ensure long-term structural integrity and safety, our formulations are tested according to the ISO 4587 Standard for Tensile Lap-Shear Strength of Rigid-to-Rigid Bonded Assemblies. This international benchmark verifies that the Polyurethane Structural Adhesive maintains its load-bearing capacity under extreme environmental conditions. By adhering to these rigorous testing protocols, we ensure that every bond provides the reliability and crash-resistance required for modern high-performance engineering.