Thermal Grease | TGR-series

Product Highlights

- Low thermal resistance

- Slightly fluid to fill the void

- Stable and compliant with RoHS and

other environmental requirements

Applications

- CPU (laptop, desktop, server)

- ASIC chips

- Microprocessor/graphics processor

- Northbridge chipset

- Integrated Gate Bipolar Transistor (IGBT)

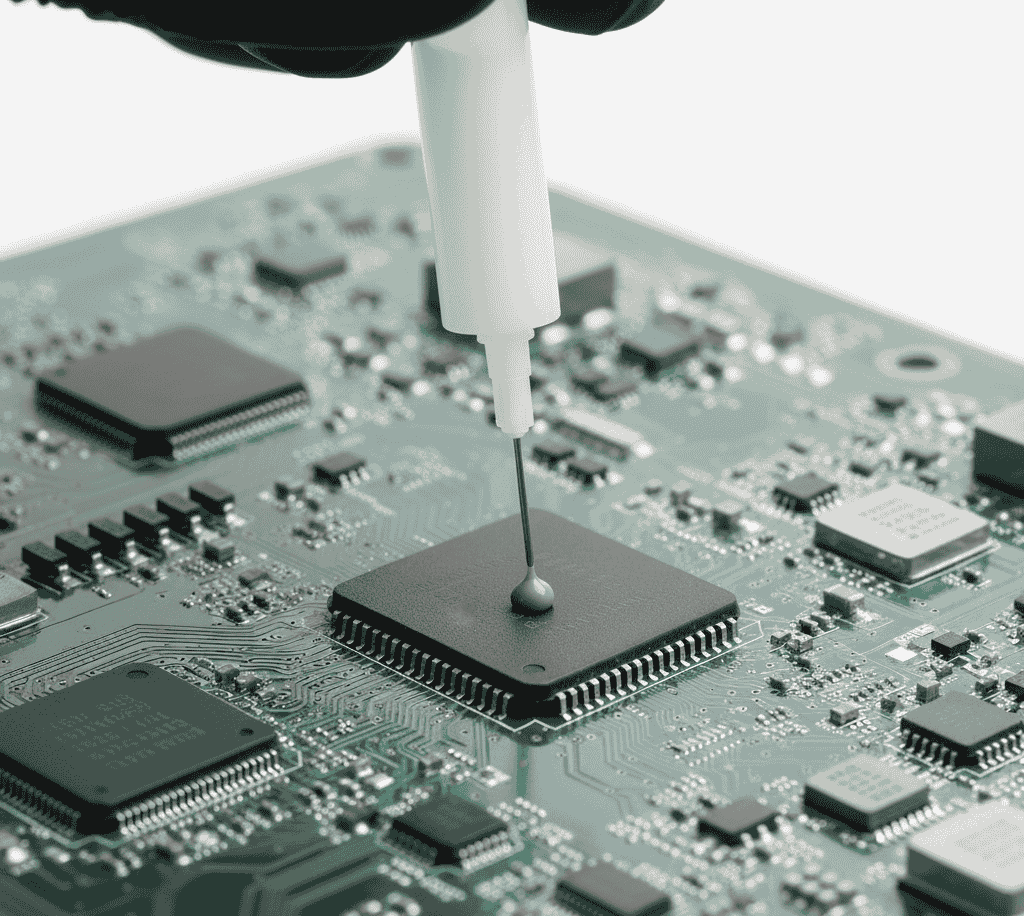

TGR series is a high-performance thermal grease based on silicone resin, designed to provide excellent heat dissipation. With superior wetting characteristics, it effectively fills the irregular micro-structures on component surfaces, forming an interface with very low thermal resistance. The grease is highly reliable, and it will not dry, precipitate, or harden over time. Its typical coating thickness ranges between 0.05 to 0.15mm.

TGR is ideal for addressing heat dissipation challenges in general components. In its viscous liquid form, it evenly fills gaps on the surfaces of components, ensuring optimal thermal transfer. With low thermal resistance, it can be applied via silk screen printing or squeegee coating onto heat sinks or thermal modules. Additionally, the material is RoHS compliant and meets other environmental standards, making it safe for both components and the environment.

Our thermal grease is engineered for high-performance applications that require ultra-thin bond lines and minimal thermal resistance. To guarantee environmental safety and industry-leading quality for global export, all our formulations strictly adhere to REACH and RoHS compliance. This ensures that our thermal grease provides a safe, reliable, and high-conductivity interface for sensitive consumer electronics and industrial power modules.

SPECIFICATIONS TABLE

| Part Numbers | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Parameters | Units of Measure | TGR10 | TGR10HV | TGR1S | TGRZT | TGR31 | TGR31W | TGR4G | TGR50 |

| Colour | – | White | White | White | Gray | Gray | White | Gray | Gray |

| Thermal Conductivity | W/m·K | 1.0 | 1.0 | 1.5 | 2.0 | 3.1 | 3.1 | 4.0 | 5.0 |

| Thermal Resistance | oC·in²/W@50psi | 0.025 | 0.025 | 0.027 | 0.023 | 0.009 | 0.009 | 0.010 | 0.007 |

| oC·cm²/W@50psi | 0.161 | 0.161 | 0.174 | 0.148 | 0.058 | 0.058 | 0.065 | 0.045 | |

| Viscosity | cps@23oC | 5.0×104 | 15.0×104 | 1.2×10⁵ | 8.0×104 | 1.5×10⁵ | 1.5×10⁵ | 1.3×10⁵ | 2.5×10⁵ |

| Flammability Rating | – | V0 | V0 | V0 | V0 | V0 | V0 | V0 | V0 |

| Volume Resistivity | Ω·cm | ≥7.0×10¹¹ | ≥7.0×10¹¹ | ≥1.0×10¹² | ≥9.0×1013 | ≥1.0×1010 | ≥1.0×1010 | ≥1.0×10⁹ | ≥1.0×10⁹ |

| Density | g/cm³ | 2.50 | 2.50 | 2.55 | 2.60 | 2.75 | 2.75 | 2.82 | 2.92 |

| Dielectric Constant | @1MHz | 5.8 | 5.8 | 6.5 | 6.3 | 7.5 | 7.5 | 7.8 | 8.5 |

| Operating Temperature | oC | -50~+150 | -50~+150 | -50~+150 | -50~+150 | 50~+150 | -50~+150 | -50~+15 | -50~+150 |

| RoHS | – | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |