Silane polyether adhesive SMP5110F | for industrial application

Product Features of Silane polyether adhesive SMP5110F

- Environmentally friendly products: fast curing, low VOC, non-toxic and odorless,

no pollution or corrosion to the substrate. - Surface coating: After the surface is dry, it can be sprayed with paint for coloring.

- Good operability: single component, easy to operate,

within the temperature range of 4 ℃~40 ℃ - It has good extrusiveness and can be directly applied

by extruding with a glue gun. - Excellent adhesion: to metals, glass, ceramics, wood, PVC, PC, PA

- The material has excellent adhesion.

- Excellent weather resistance, aging resistance, dielectric and

mechanical properties.

Products Applications

- Adhesive and sealing of windshields and side windows of trains/buses/cars/trucks, etc.

SMP5110SF Locomotive-Grade Silane-Modified Polyether Adhesive is a high-performance, single-component adhesive that cures through a neutral process. It is environmentally friendly and free from toxic or hazardous substances.

This adhesive offers excellent adhesion to a wide range of substrates, including metal, glass, ceramics, wood, polyvinyl chloride (PVC), and polycarbonate (PC). Once fully cured, the surface can be painted or coated.

SMP5110SF is ideal for bonding and sealing applications, particularly for windshields and side windows in trains, buses, and automobiles.

SPECIFICATIONS TABLE SMP5110SF

Recommending:

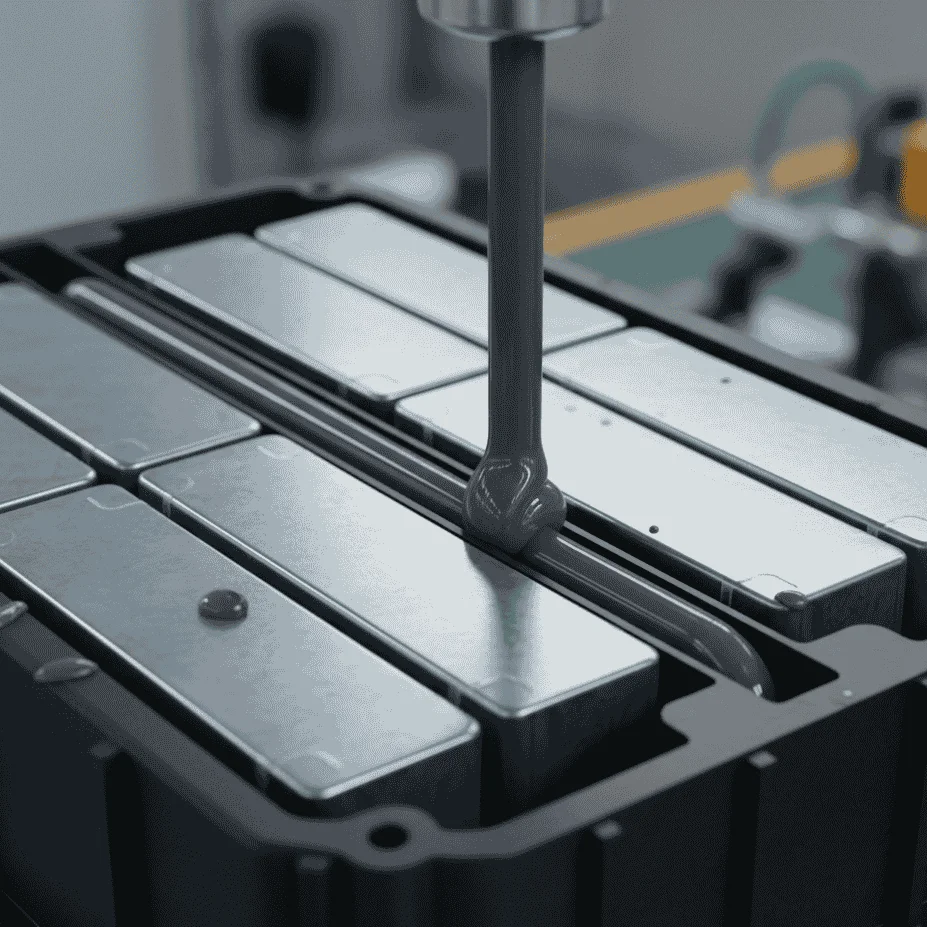

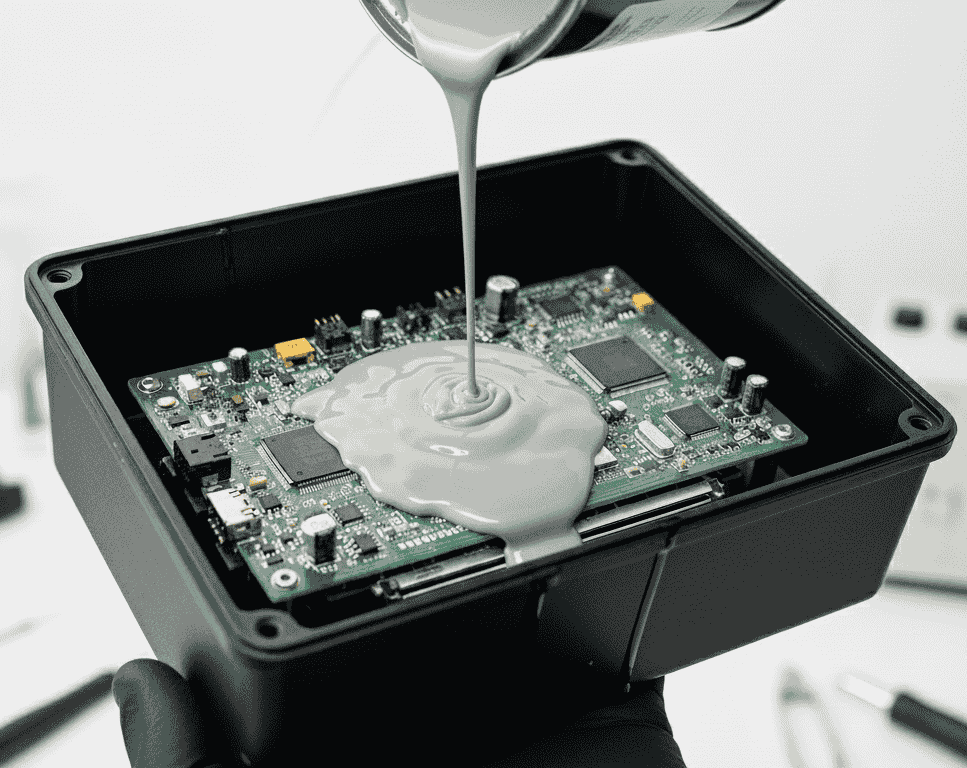

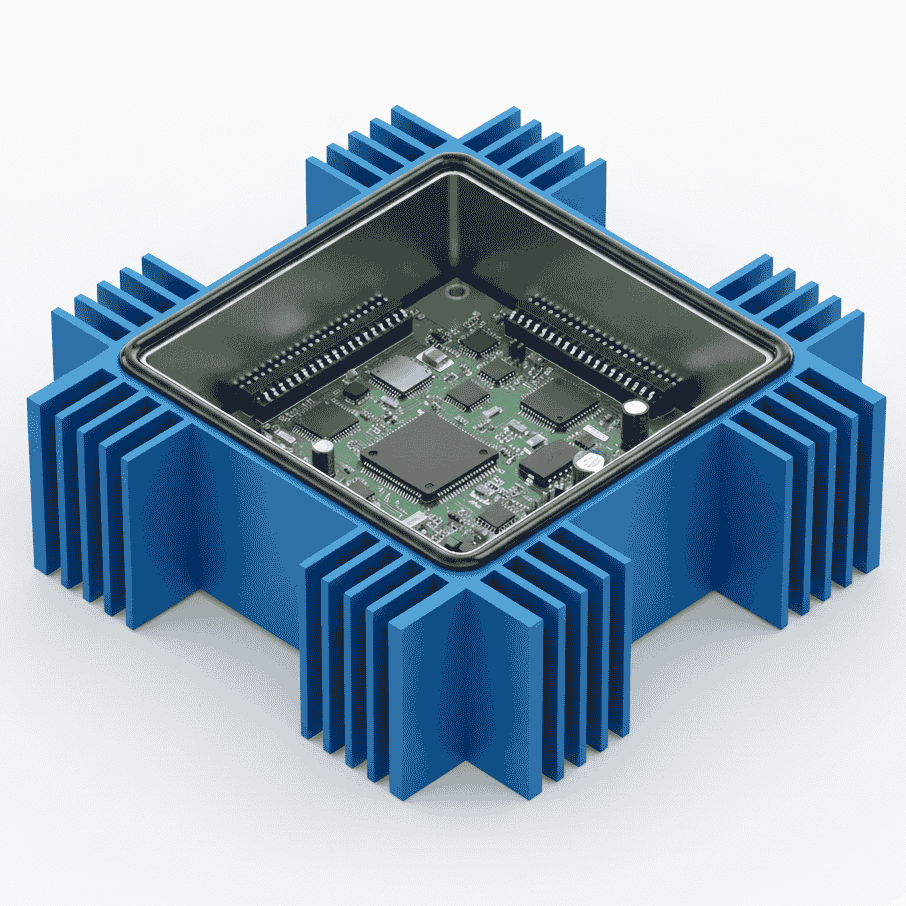

TPC-series | Thermal Potting Compound

FIP Form-in-Place-Gasket

RF Absorber Soft Magnetic

| Item | Parameter | Test Standard |

| color | black | – |

| Curing method | moisture curing | – |

| Working temperature (°C) | -40~+100 | – |

| Dry time (min) | 5~15 | GB/T 13477-2002 |

| Curing rate (mm/24h) | 4~5 | – |

| Density (g/cm ³) | 1.40~1.60 | GB/T 13477-2002 |

| Hardness (Shore A) | 45 | GB/T 531-2009 |

| Tensile strength (MPa) | 2.5~3.5 | GB/T 528-2009 |

| Tensile elongation at break (%) | ≥400 | GB/T 528-2009 |

| Shear strength (MPa) | ≥3 | GB/T7124-2008 |

| Tear strength (N/mm) | 20 | GB/T 529-2008 |

| Storage period (month) | 6 | BS 3712-2 |

Instructions for Use

Before using this product, operators must carefully read all safety information provided.

Ensure the application surface is clean, dry, and free from dust or debris.

Apply the product using a manual or pneumatic caulking gun.

Maintain adequate ventilation during both application and curing processes.

To achieve optimal bonding results, perform a bonding test before large-scale use. Regular peel tests are also recommended throughout the construction process to ensure consistent performance.

Safety Precautions

This product is non-toxic once fully cured. However, avoid contact with the eyes before curing. In case of eye contact, rinse immediately with plenty of water and seek medical attention. Keep uncured product out of reach of children.

Packaging

Available in 300ml net content packaging.

Storage and Shelf Life

Store in a cool, dry environment at temperatures below 27°C. Shelf life is 6 months from the production date.

Technical Overview & Compliance

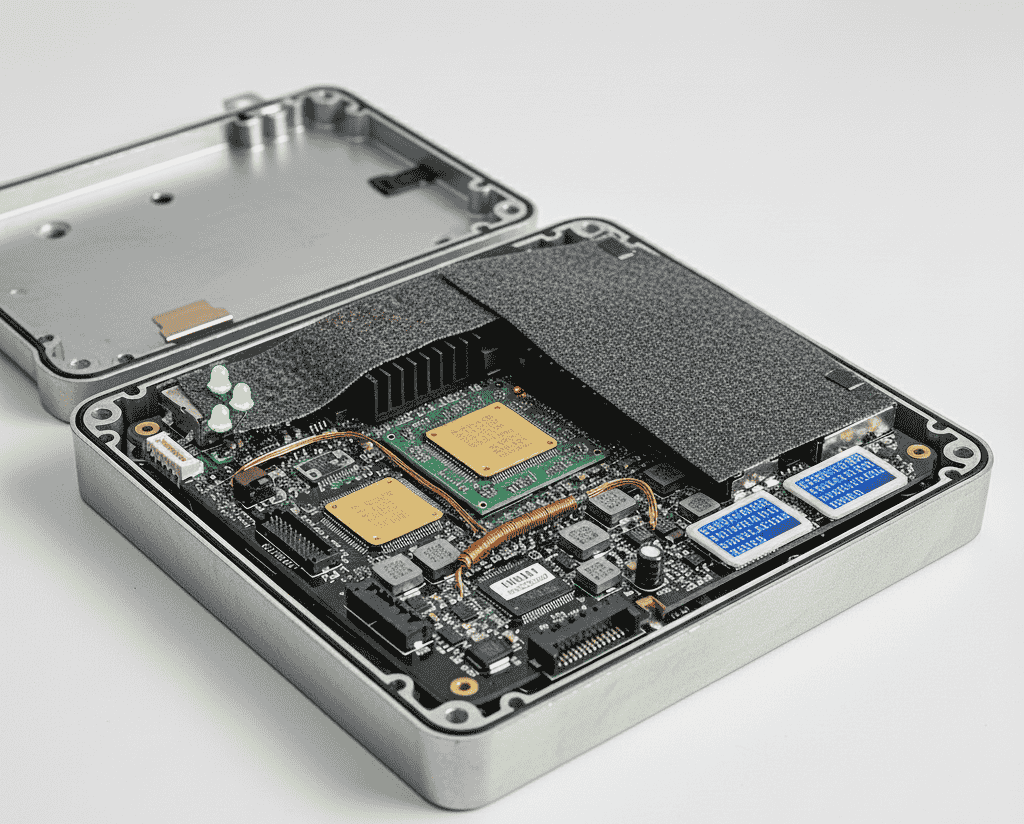

The Silane Modified Polyether Adhesive represents a hybrid chemistry breakthrough, offering a solvent-free and isocyanate-free bonding solution. Its unique molecular structure allows for exceptional adhesion to a wide range of substrates—including powder-coated metals, glass, and engineering plastics—without the need for aggressive surface pre-treatments. This adhesive is particularly valued in the transportation and renewable energy sectors for its ability to remain flexible under high vibration and its compatibility with industrial paint processes.

To ensure this material meets the rigorous demands of modern manufacturing and environmental safety, it is formulated in alignment with the GEIA (Government Electronics & Information Technology Association) technical standards for materials used in high-reliability systems. This ensures that the Silane Modified Polyether Adhesive provides the long-term chemical resistance and structural integrity required for mission-critical infrastructure and advanced electronic enclosures.