PU1200 polyurethane hot melt adhesive

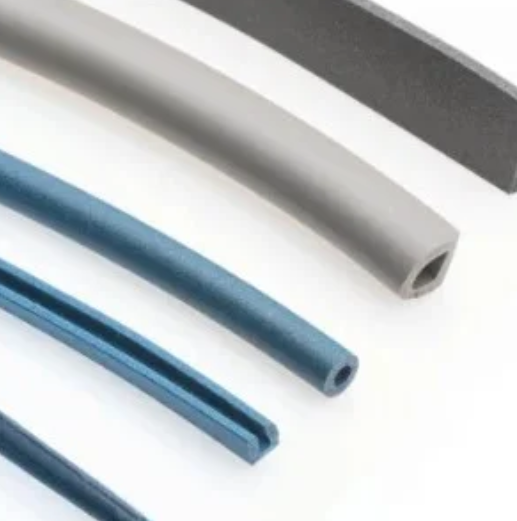

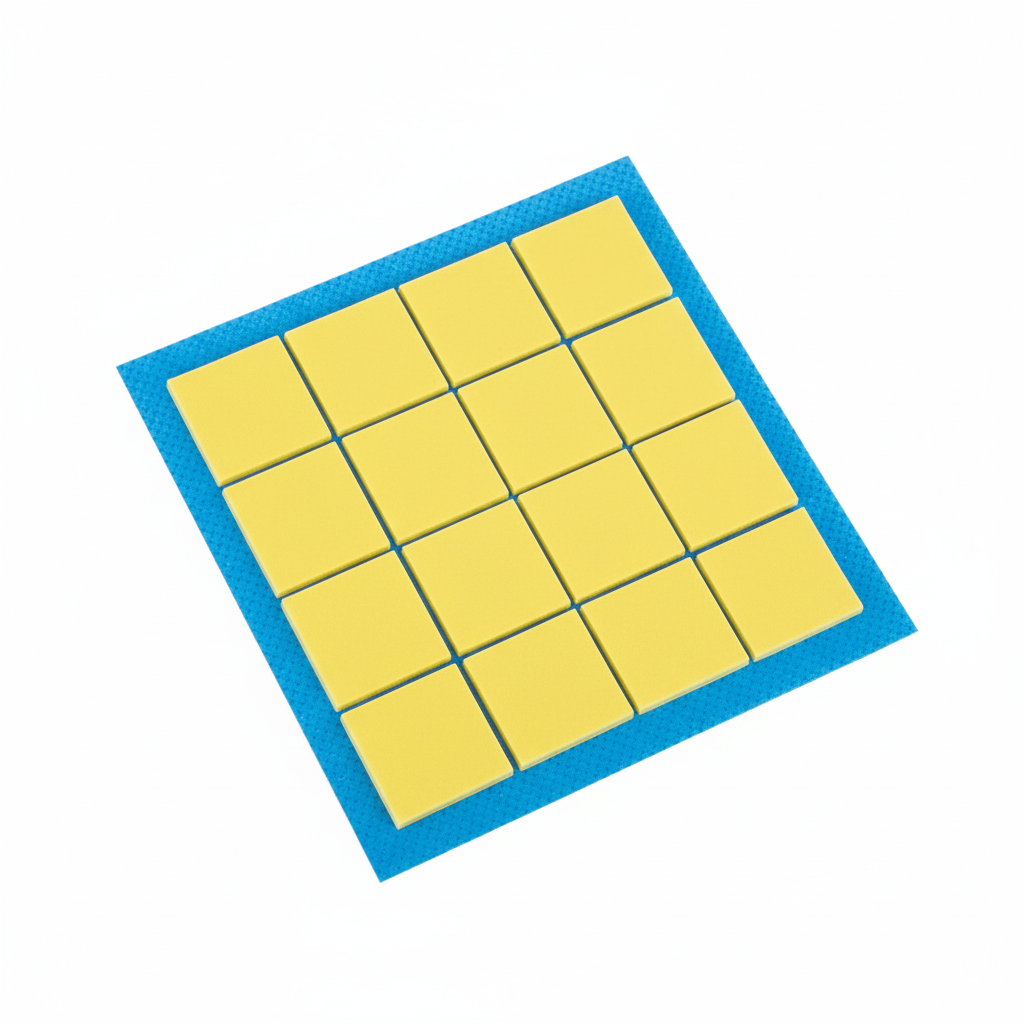

PU1200 is a 100% solids, moisture-reactive polyurethane hot melt adhesive designed for both self-adhesion and mutual bonding of materials such as PC, ABS, PVC, aluminum, stainless steel, and glazed glass. Once applied and cooled, it delivers sufficient initial strength to support subsequent processing steps. After full curing, the adhesive offers outstanding resistance to heat, water, and chemicals, making it particularly well-suited for bonding plastics in electronic applications.

Product Highlights of polyurethane hot melt adhesive

- Moisture reactive type

- Suitable for bonding between different materials

- Moisture reactive type

- After curing, it has excellent heat resistance, water resistance, and chemical resistance

- Widely used in the electronics industry

Product Application of polyurethane hot melt adhesive

This adhesive is primarily designed for bonding various plastics and metals in the electronics industry. Since material surface properties can vary significantly, it is strongly recommended to conduct preliminary tests before actual use.

SPECIFICATIONS TABLE

Recommending:

EC-series | EMI Electrically Conductive Elastomer

Thermal Pad TFP L2 Series | 2.2 ~ 3.0 W/mK

RF Absorber Hybrid Gel | SF Series

| Basic characteristics | Unit | component |

| appearance | – | black solid |

| density | g/cm3 | 1.1±0.05 |

| solid content | % | 100 |

| Melting viscosity @ 100 ° C | cps | 5000±2000 |

| Opening hours @ 25 ° C | min | 2~6 |

Anticipated matters

Please read the safety manual before use to understand the relevant preventive measures and safety recommendations. For chemicals that do not require labeling, observe in advance and take corresponding preventive measures.

Product Application

It is mainly suitable for bonding various plastics and metals in the electronics industry. The surface properties of each material vary greatly, and it is recommended to conduct pre experiments before use.

Product Operation

The construction site should have a good ventilation system, and the recommended construction temperature is between 100-130 °C.

GBT ViaBON PU1200 belongs to the moisture responsive polyurethane hot melt adhesive category. Please use professional equipment for reactive hot melt adhesives. If ordinary hot melt adhesive equipment is used, it may cause moisture to seep into the product due to poor airtightness, resulting in curing when in contact with the product, which will damage the adhesive machine or affect its use.

Please assemble the parts immediately after gluing, so that the glue can achieve good wetting effect, which will help with the bonding effect.

In order to achieve complete curing, it is best to place the finished product in a suitable working environment with appropriate temperature and humidity (recommended temperature: 23-25 ° C, relative humidity of about 65%).

It is recommended to fully cure the assembled electronic products before conducting subsequent related tests.

Cleaning

For uncured products, construction equipment can be cleaned with specialized cleaning agents and must be thoroughly rinsed clean.

The fully cured adhesive is difficult to remove and may require long-term immersion in NMP solvent for removal.

Packing Specification

30ml plastic tube packaging, 300ml support packaging, 25kg drum packaging

Shelf life/storage

Recommended storage temperature: 10-25 ° C, stored in a cool and dry environment

Shelf life: 6 months in original packaging

Precautions

This product is reactive polyurethane. Employees who are allergic to polyurethane products are not recommended to operate.

Due to the need to use the product at high temperatures, please be sure to wear appropriate clothing, gloves, protective goggles, and other personal protective equipment.

Ready to use, do not expose to air for extended periods of time

Maintain first in, first out use of materials.

Cleaning agents should only be used once and should not be mixed into the product

Do not eat in the workplace

Technical Overview & Compliance

Our Polyurethane Hot Melt Adhesive (PUR) combines the processing speed of traditional hot melts with the structural strength of a reactive cross-linking polymer. Once applied, the adhesive reacts with atmospheric moisture to form a permanent, thermoset bond that will not re-melt under high-temperature exposure. This makes it an ideal solution for bonding low-surface-energy plastics, glass, and metals in compact electronic enclosures where thin-line bonding and immediate handling strength are required for automated assembly.

To ensure consistent performance in global manufacturing environments, our PUR formulations are evaluated against the ISO 9142 standard for Adhesives – Guide to the Selection of Standard Laboratory Ageing Conditions. This compliance ensures that the Polyurethane Hot Melt Adhesive maintains its bond integrity against humidity, chemical exposure, and thermal shock. By meeting these international benchmarks, we guarantee a reliable, long-lasting adhesive solution that withstands the rigorous demands of the consumer electronics and automotive industries.