Low Volatile Silicone Sealing Adhesive NF1015-10

Product Features of Low Volatile Silicone Adhesive

- Single component – room temperature (moisture) curing

- Silicone rubber substrate

- Tin free

- Excellent sealing performance

- High elasticity and softness

- Low volatility, low oil permeability

- Can maintain good reliability even under low voltage conditions

- High temperature and moisture resistance

- Does not contain acidic or alkaline agents

Product Application of Low Volatile Silicone Adhesive

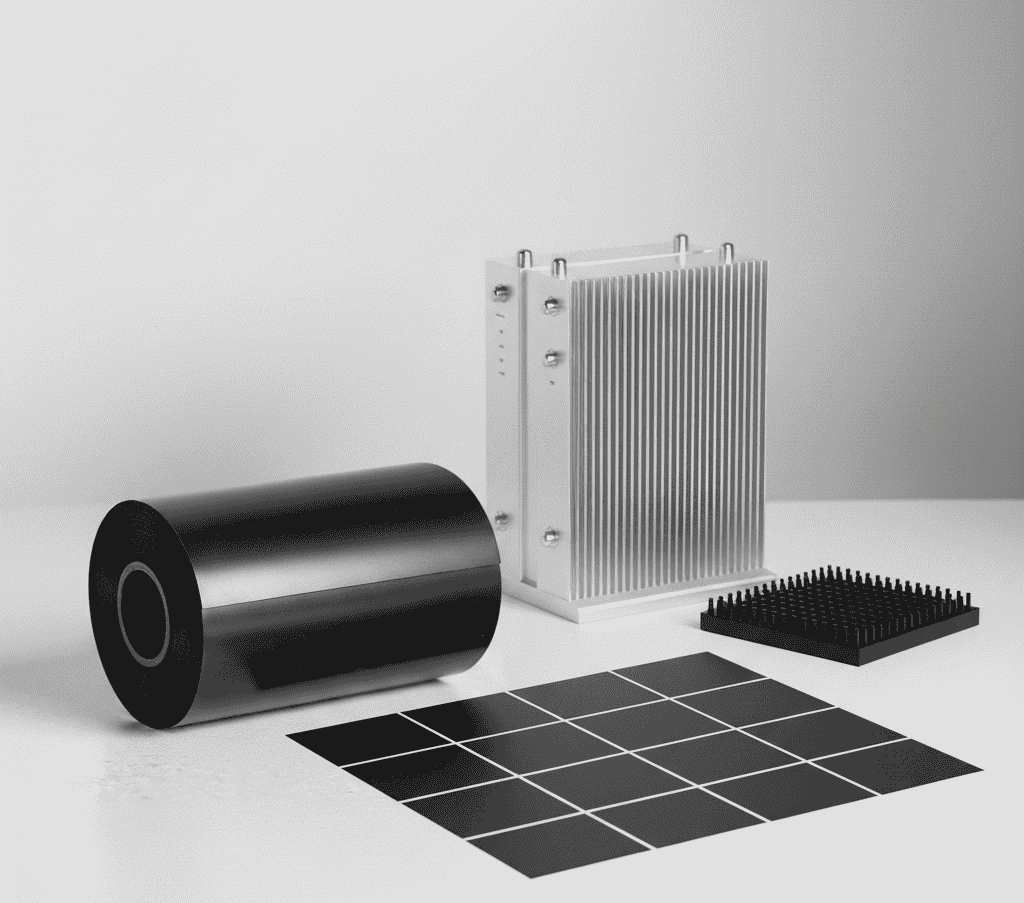

- Applied for sealing or bonding of automotive components and photovoltaic products, such as junction boxes and aluminum frames.

- General sealing or bonding of various electrical components.

Technical Overview & Compliance of Low Volatile Silicone Adhesive

Our Low Volatile Silicone Sealing Adhesive is an advanced elastomeric solution designed for applications where standard silicones might outgas volatile organic compounds (VOCs). These volatiles can condense on sensitive lenses, sensors, or circuit contacts, leading to fogging or electrical failure. This adhesive features a controlled polymerization process that significantly reduces low-molecular-weight siloxanes, making it indispensable for aerospace instrumentation, LiDAR housings, and cleanroom equipment.

To ensure performance in high-stakes environments, this material is rigorously tested according to the NASA SP-R-0022A (ASTM E595) Outgassing Data for Selecting Spacecraft Materials. This compliance ensures that the Low Volatile Silicone Sealing Adhesive meets the strict Total Mass Loss (TML) and Collected Volatile Condensable Material (CVCM) limits required for spaceflight and deep-vacuum industrial processes. By utilizing these high-purity formulations, engineers can maintain the long-term clarity and reliability of sensitive optoelectronic systems.

SPECIFICATIONS TABLE

Recommending

RF Absorber Injection Molded Sheet MW1000-series

GRF-series | Thermally Conductive Graphite Film

EMI Finger Stock Gasket

| Item | Unit | NF1015-10 | Test Standard |

| appearance | – | Black/White/Grey | visual |

| Type of resin | – | Single component silicon-based | – |

| Extrusion rate (55cc, 1.5mm nozzle @60psi) | g/min | 10±2 | GBA |

| Surface drying time | min | 10~20 | GBA |

| Basic curing time | hr | 2~4 | GBA |

| Curing speed | mm/24h | ≥2.0 | GBA |

| density | g/cm3 | 1.5 | ASTM D792 |

| hardness | Shore A | 35±5 | ASTM D2240 |

| tensile strength | MPa | ≥1.8 | ASTM D412 |

| Elongation at break | % | ≥300 | ASTM D412 |

| Shear strength (aluminum) | MPa | ≥2.0 | ASTM D1002 |

| volume resistivity | Ω-cm | ≥1.0×1014 | ASTM D257 |

| compressive strength | kV/mm | ≥15 | ASTM D149 |

| Flame retardant rating | – | HB | UL94 |

| Working temperature range | ° C | -60~200 | GBA |

| RoHS | – | Yes | GBA |

Standard Packaging

- Available in 55cc and 300cc syringes

- Custom packaging options available upon request

Storage and Shelf Life

- Store in a cool, dry, sealed environment at temperatures between -20°C and 30°C

- Shelf life: 6 months

Instructions for Use

• Surface Preparation

Thoroughly clean the bonding surface using sandpaper or solvents such as toluene or xylene to remove rust, oil, dust, and other contaminants that may affect adhesion. Exercise caution when using solvents on plastic materials, as some solvents may damage certain plastic surfaces.

• Application

Load NF1015-10 into the FIP dispensing machine. Select an appropriate dispensing needle size for your application. Dispense the adhesive and immediately align and press the bonding surfaces together before the adhesive surface begins to dry.

• Product Handling After Opening

It is recommended to use the product completely once opened. If any material remains, seal the container tightly using the removed nozzle tip and store at room temperature for a few days.

Storage Precautions

NF1015-10 reacts with moisture in the air and begins to cure on the surface. The curing speed may vary depending on environmental temperature and humidity.

Note: If humidity exceeds 100% and water droplets form on the adhesive, hydrolysis may occur before crosslinking begins, weakening the cured product and inhibiting full curing.

During the curing process, electrical insulation properties may temporarily decline. However, in most cases, the material will regain its full insulation performance once fully cured.

Avoid contact with solder or certain materials that may inhibit curing.

Do not cure the product in completely enclosed areas using condensation methods.

Ensure all bonding surfaces are clean and free from moisture, oil, and contaminants. Primers may be required for certain substrates to improve adhesion.

Safety and Hygiene Guidelines

- Use NF1015-10 in a well-ventilated area, as methanol gas is released during curing. If discomfort occurs, move to an area with fresh air.

- Uncured material may irritate skin and mucous membranes. Avoid prolonged skin contact and prevent eye contact.

- In case of eye contact: Rinse immediately with water for at least 15 minutes and seek medical attention.

- For skin contact: Wipe off with a dry cloth and wash the area with soap and water.

- Individuals wearing contact lenses should take extra precautions, as uncured adhesive may cause lenses to adhere to the eyes.

- Avoid touching your eyes during use. Wear protective equipment such as safety glasses.

- Keep out of reach of children.

- For detailed safety information, please consult the Material Safety Data Sheet (MSDS).