NF1012-10 Rapid Moisture-curing Silicone Sealing Adhesive

Product Highlights of Moisture-curing Silicone Sealing

- Monocomponent – room temperature (moisture) curing

- Silicone rubber substrate

- Tin free

- Excellent sealing performance

- High elasticity and softness

- Super adhesion

- It can also maintain good reliability under the condition of low-voltage transformer

- High temperature resistance & moisture resistance

- Acid and alkali free

Applications of Moisture-curing Silicone Sealing

- Applies to sealing or bonding of automotive parts, photovoltaic products, such as junction boxes and aluminum frames.

- General sealing or bonding of various electrical components.

Descriptions of of Moisture-curing Silicone Sealing

The GBA NF series is a non-conductive sealing adhesive known for its excellent resilience and environmental sealing properties. It can be applied using either manual or automatic dispensing equipment. The NF series features low hardness and good elasticity, providing strong adhesion to various metal and plastic surfaces. Its primary applications include wireless communication base station equipment, automotive and electrical appliances, consumer electronics, and other related industries.

NF1012-10 is a fast-curing, single-component silicone sealing adhesive independently developed and manufactured by Goodbon. It cures through a moisture-activated, non-sensitive process, offering excellent elasticity and reliable sealing performance after vulcanization. This product is well-suited for use with professional automatic dispensing machines.

SPECIFICATIONS TABLE

Recommending:

Hybrid Thermal & RF Absorber SFA-series | Gel

RF Absorber Foam FW-series

Phase Change Material PCF-series Thermally Conductive

| Typical performance | Unit | NF1012-10 | Test Method |

| Color | – | Black/White | Visual |

| Resin | – | monocomponent silicon | – |

| Extrusion Rate(55cc、.5mm needle@60psi) | g/min | 8±2 | GBA |

| Tack-free Time | min | 5~15 | GBA |

| Gel Time | h | 1~2 | GBA |

| Curing Speed | mm/24h | ≥3.0 | GBA |

| Density | g/cm3 | 1.35 | ASTM D792 |

| Hardness | Shore A | 35±5 | ASTM D2240 |

| Tensile Strength | MPa | ≥1.5 | ASTM D412 |

| Elongation | % | ≥300 | ASTM D412 |

| Shear Strength(Al) | MPa | ≥1.0 | ASTM D1002 |

| Volume Resistivity | Ω-cm | ≥1.0×1014 | ASTM D257 |

| Dielectric Strength | kV/mm | ≥15 | ASTM D149 |

| Flammability | – | HB | UL94 |

| Temperature Range | °C | -60~200 | GBA |

| RoHS | – | Yes | GBA |

Packaging

- Available in 55cc and 300cc syringes

- Custom packaging available upon request

Storage & Shelf Life

- Store in a sealed container in a cool, dry environment at -20°C to 30°C

- Shelf life: 6 months under proper storage conditions

Usage Instructions

Surface Preparation:

Before application, thoroughly clean the surface using sandpaper or suitable solvents (e.g., toluene, xylene) to remove rust, oil, dirt, or any contaminants that could affect adhesion. Be cautious when using solvents on plastic, as some may cause damage.

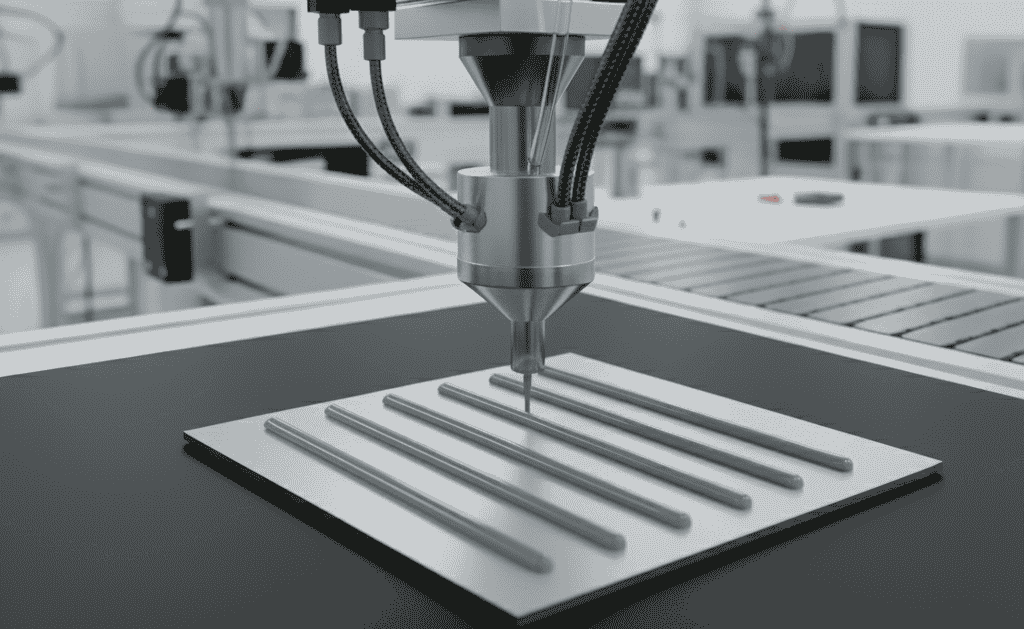

Application:

Load NF1012-10 into a FIP (Form-in-Place) dispensing machine. Select the appropriate dispensing needle size and apply the adhesive. Quickly attach the mating surface before surface curing begins.

Storage After Opening:

For best results, use the entire contents in one go. If any material remains, keep the used nozzle attached and reseal the container tightly. The product may still be usable for several days if stored properly.

Storage Precautions

- NF1012-10 reacts with ambient moisture, starting the surface curing process. Curing speed will vary depending on environmental temperature and humidity.

- In high humidity (over 100%), condensation may occur. If water droplets form on the curing adhesive, a hydrolysis reaction may occur instead of proper crosslinking, resulting in reduced strength and residual surface tackiness.

- Electrical insulation properties may temporarily decline during curing but will typically return to normal after full curing.

- Avoid contact with flux or other incompatible materials that may inhibit curing.

- Do not use condensation-cure products in fully enclosed spaces.

- Ensure bonding surfaces are free from moisture, oils, and contaminants. Primers may be necessary for certain substrates.

Safety & Hygiene Guidelines

- Always work in a well-ventilated area when using NF1012-10. Methanol gas is released during curing. If discomfort occurs, move to a fresh-air environment immediately.

- Uncured adhesive may cause skin and eye irritation. Avoid direct contact. If it gets into the eyes, rinse thoroughly with water for at least 15 minutes and seek medical attention.

- In case of skin contact, wipe off the adhesive with a dry cloth, then wash the area with soap and water.

- Contact lens users should be especially cautious, as adhesive may bond lenses to the eyes.

- Avoid touching your face or eyes during use. Always wear appropriate personal protective equipment such as safety goggles and gloves.

- Keep out of reach of children.

- For more detailed safety information, please refer to the Material Safety Data Sheet (MSDS).

Technical Overview: To ensure peak performance in critical electronics, our materials are verified against industry-leading benchmarks. By adhering to the IPC Standards for Electronic Manufacturing, we ensure that every Low Volatile Silicone Sealing Adhesive maintains the chemical purity required for modern high-density circuit assemblies and sensor housings.