NF1011-10 Wide-Temperature Silicone Sealant

Product Features of Wide-Temperature Silicone Sealant

- Single-component, neutral-cure adhesive that is non-corrosive to materials. It features a simple application process, fast curing, and maintains its original color after curing.

- Excellent adhesion to a variety of substrates including glass, metal, plastic, and more.

- Strong resistance to oils.

- Outstanding temperature resistance, maintaining stable performance across a wide range from -60°C to +260°C.

Applications of Wide-Temperature Silicone Sealant

- Suitable for sealing and bonding in automotive components and photovoltaic products, such as junction boxes and aluminum frames.

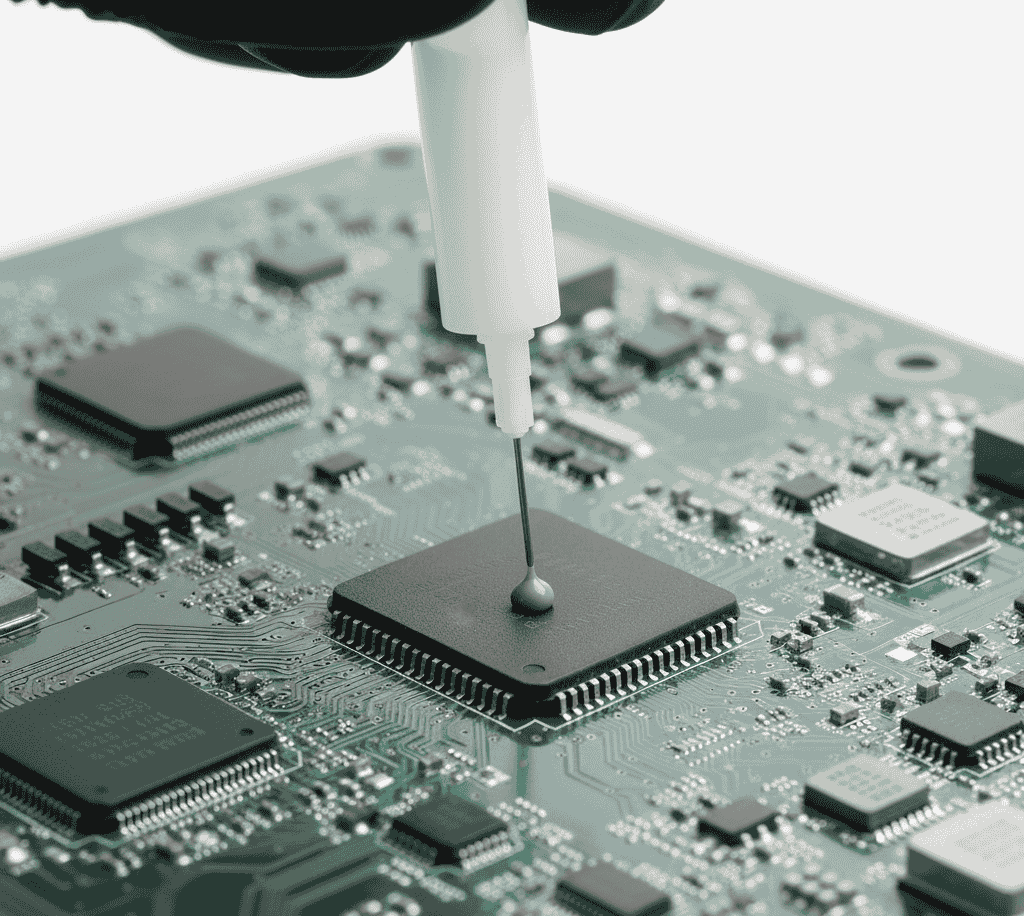

- Ideal for general-purpose sealing or bonding of various electronic and electrical components.

GBA NF Series – Non-Conductive Sealing Adhesive

The GBA NF series is a range of non-conductive sealing adhesives offering excellent resilience and environmental sealing capabilities. These adhesives can be applied using either manual dispensing tools or automated dispensing equipment. Featuring low hardness and high elasticity, GBA NF adhesives provide strong adhesion to a variety of metal and plastic surfaces.

Typical applications include wireless communication base stations, automotive components, electrical appliances, consumer electronics, and other related fields.

NF1011-10 is a fast-curing, one-component silicone sealing adhesive developed and manufactured in-house by GBA. It cures through a moisture-activated, non-sensitive process and delivers excellent elasticity. Once vulcanized, it forms a strong, durable seal. This product is especially well-suited for use with automated dispensing systems in professional production environments.

SPECIFICATIONS TABLE

| Typical performance | Unit | NF1011-10 | Test Method |

| Color | – | Black/Grey | Visual |

| Resin | – | monocomponent silicon | – |

| Extrusion Rate( 55cc、1.5mm needle@60psi) | g/min | 2 ±0.5 | GBA |

| Tack-free Time | min | ≤4 | GBA |

| Gel Time | h | 1 | GBA |

| Curing Speed | mm/24h | ≥4.0 | GBA |

| Density | g/cm3 | 1.35 | ASTM D792 |

| Hardness | Shore A | 45±5 | ASTM D2240 |

| Tensile Strength | MPa | ≥1.0 | ASTM D412 |

| Elongation | % | ≥200 | ASTM D412 |

| Shear Strength(Al) | MPa | ≥1.5 | ASTM D1002 |

| Volume Resistivity | Ω-cm | ≥1.0 ×1014 | ASTM D257 |

| Dielectric Strength | kV/mm | ≥10 | ASTM D149 |

| Flammability | – | HB | UL94 |

| Temperature Range | °C | -60~260 | GBA |

| RoHS | – | Yes | GBA |

PACKAGING

- Available in 55cc and 300cc syringes

- Custom packaging options available upon request

STORAGE & SHELF LIFE

- Store in a sealed container in a cool, dry environment between -20°C and 30°C

- Shelf life: 4 months from the date of manufacture

STORAGE PRECAUTIONS

- NF1011-10 reacts with atmospheric moisture and begins surface curing upon exposure. The curing speed will vary depending on temperature and humidity levels.

- If the humidity exceeds 100% and condensation forms on the curing surface, hydrolysis may occur before cross-linking, which can compromise the cured rubber’s strength and leave a tacky surface.

- Electrical insulating properties may temporarily decrease during the curing process. In most cases, full insulation performance is restored once fully cured.

- NF1011-10 may not cure properly if in contact with flux or certain incompatible materials.

- Do not use condensation-cure silicone products in completely enclosed environments.

- Ensure all bonding surfaces are free of water, oil, dirt, and other contaminants. Use a suitable primer on certain substrates as needed.

USAGE INSTRUCTIONS

Surface Preparation:

- Clean surfaces thoroughly using sandpaper or solvents (e.g., toluene or xylene) to remove rust, oil, dirt, or other contaminants that could hinder adhesion.

- Exercise caution when using solvents on plastic surfaces, as some plastics may be sensitive or become damaged.

Application:

- Load NF1011-10 into an FIP (Form-in-Place) dispensing machine.

- Select the appropriate dispensing needle size and apply the adhesive.

- Bond the mating surface promptly before surface curing begins.

Storage After Opening:

- For best results, use the entire contents at once.

- If unused material remains, reseal the container tightly using the removed nozzle as a plug. Properly sealed, the product can be stored for several days.

SAFETY & HYGIENE

- Always use NF1011-10 in a well-ventilated area, as methanol gas is released during curing. If discomfort occurs, move to a fresh air environment.

- Uncured adhesive may irritate skin and mucous membranes. Avoid contact with eyes and prolonged skin exposure.

- In case of eye contact, rinse immediately with water for at least 15 minutes and seek medical attention.

- For skin contact, wipe off the adhesive with a dry cloth and wash thoroughly with soap and water.

- Contact lens wearers should take extra caution, as adhesive can bond lenses to the eyes.

- Avoid touching your eyes while handling the product. Use protective gear such as safety glasses where appropriate.

- Keep out of reach of children.

- For full safety guidelines, consult the Material Safety Data Sheet (MSDS).

Technical Overview & Compliance of Wide-Temperature Silicone Sealant

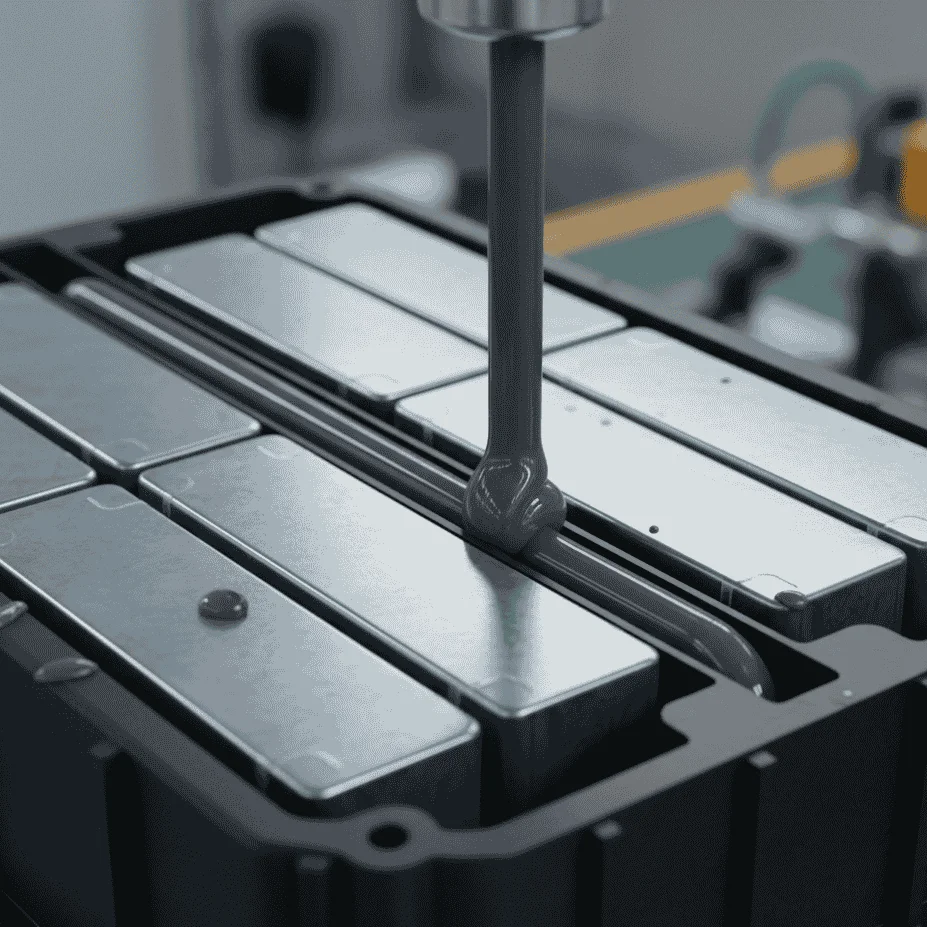

The Heat & Cold Resistance Silicone Sealing Adhesive is a specialized elastomeric compound designed to survive “thermal shock”—the rapid transition between extreme cold and intense heat. Unlike standard adhesives that become brittle or liquify, this silicone maintains its elongation and tensile strength, making it the ideal choice for EV battery packs, aerospace engine sensors, and high-altitude telecommunications. Its non-corrosive chemistry ensures it won’t damage sensitive copper traces or delicate electronic junctions during operation.

To guarantee reliability in the most punishing environments, our formulations are tested in accordance with the JEDEC JESD22-A104 Temperature Cycling standards. This benchmark verifies that the Heat & Cold Resistance Silicone Sealing Adhesive can withstand hundreds of thermal cycles without delamination or loss of seal integrity. By meeting these rigorous solid-state industry requirements, we provide a sealing solution that ensures the longevity of mission-critical hardware in any climate.