TPC-series | Thermal Potting Compound

Product Highlights of Thermal Potting Compound

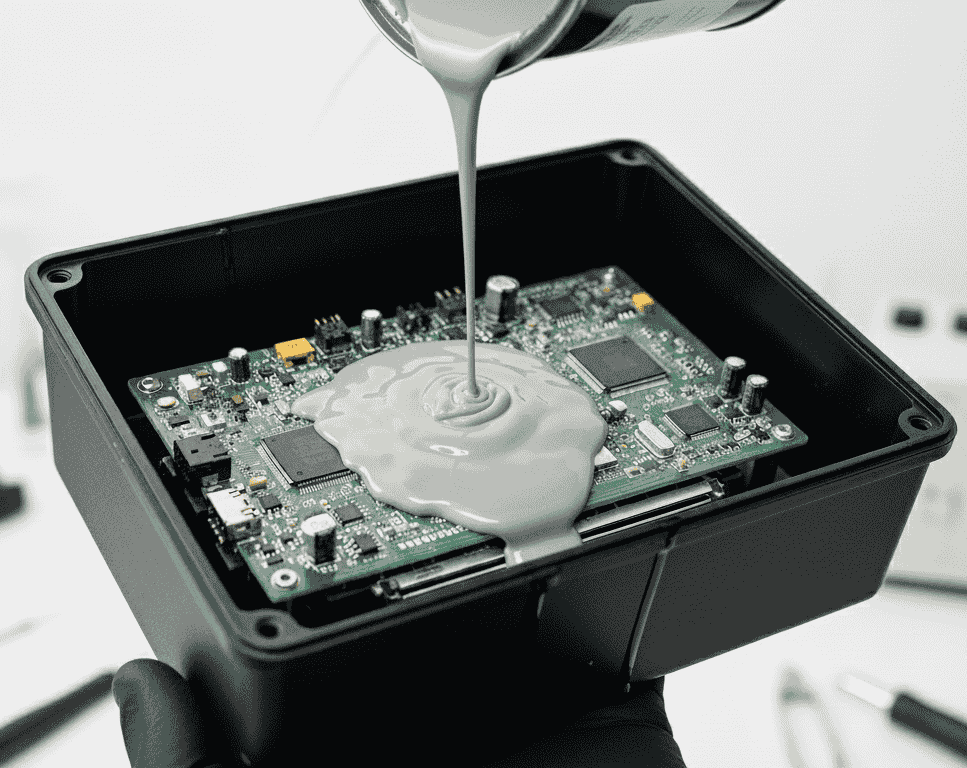

- Flow readily, easy to operate

- 1:1 mixing ratio

- Room temperature or elevated temperature curing

- Good insulation performance, temperature and weather resistance

- Wide operating temperature range

- Curing without shrinkage

- Waterproof and moisture proof

- RoHS compliance

Applications

- Power Electronics

- Printed circuit board

- Automotive electronics

The TPC series potting compound is a two-component, thermally conductive material, mixed in a 1:1 weight ratio between components A and B. It can be cured at room temperature or elevated temperatures, offering flexibility in application. Once cured, the material forms a protective layer around packaged components, shielding them from environmental factors such as vibration, humidity, and salt spray.

This highly fluid material is ideal for filling complex structures, providing protection and functionality that traditional thermal pads cannot achieve. It delivers excellent shock and vibration absorption, making it particularly well-suited for automotive electronic components where durability and reliable thermal performance are critical.

Our Thermal Potting Compound provides robust encapsulation to protect sensitive electronics from harsh environmental conditions while maintaining high heat dissipation. To ensure the highest level of environmental safety and global regulatory alignment, our formulations are strictly REACH and RoHS compliant. This guarantees that our Thermal Potting Compound delivers a safe, reliable solution for the structural integrity and thermal management of power supplies and automotive modules.

SPECIFICATIONS TABLE

| Item | Unit | TPC0740 | TPC1050 | TPC1550 | TPC2050 | TPC3055 | TPC1370R | TPC1540R | TPC1865R | ||||||||

| Type | Silicone Thermally Conductive Potting Compound | Silicone Thermally Conductive Potting Compound with Stronger Bonding Feature | |||||||||||||||

| Components | – | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B |

| Before Mixing | |||||||||||||||||

| Colour | – | Grey | White | Grey | White | Grey | White | Grey | White | Grey | White | Grey | White | Grey | White | White | Grey |

| Viscosity | cps | 1600 | 1500 | 2900 | 3100 | 6500 | 6500 | 25000 | 25000 | 15000 | 15000 | 7500 | 7500 | 7500 | 7500 | 50000 | 50000 |

| Viscosity after mixing | cps | 1500 | 3000 | 6500 | 25000 | 15000 | 7500 | 7500 | 50000 | ||||||||

| Pot Life @25°C | min | 60 | 60 | 60 | 100 | 90 | 60 | 60 | 60 | ||||||||

| mold time @25°C | hr | 1 to 2 | 1 to 2 | 1 to 2 | 1 to 2 | 1 to 2 | 1 to 2 | 1 to 2 | 1 to 2 | ||||||||

| Cure time @25°C | hr | 8 | 8 | 8 | 12 | 12 | 6 | 8 | 20 | ||||||||

| Cure time @100°C | min | 20 | 20 | 20 | 25 | 20 | 15(@150℃) | 20 | 10 | ||||||||

| After Mixing | |||||||||||||||||

| Hardness | Shore A | 40 | 50 | 50 | 50 | 55 | 70 | 40 | 65 | ||||||||

| Thermal Conductivity | W/m·K | 0.65 | 1 | 1.5 | 2 | 3 | 1.3 | 1.5 | 1.8 | ||||||||

| Dielectric Strength@1mm | kV | ≥15 | ≥15 | ≥12 | ≥13 | ≥13 | ≥15 | ≥15 | ≥15 | ||||||||

| Volume Resistivity | Ω·cm | ≥1.0×10¹⁴ | ≥1.0×10¹⁴ | ≥1.0×10¹³ | ≥1.0×10¹³ | ≥1.0×10¹⁴ | ≥1.0×10¹³ | ≥1.0×10¹³ | ≥1.0×10¹³ | ||||||||

| Density | g/cm³ | 1.5 | 1.58 | 2.25 | 2.75 | 2.95 | 2.2 | 2.25 | 2.7 | ||||||||

| Dielectric Constant | @1MHz | 3 | 3.5 | 4.5 | 6.5 | 5.5 | 4.5 | 4.5 | 5.5 | ||||||||

| Flammability Rating | UL94 | V0 | V0 | V0 | V0 | V0 | V0 | V0 | V0 | ||||||||

| Operating Temperature | oC | -50~+200 | -50~+200 | -50~+200 | -50~+200 | -50~+200 | -50~+200 | -50~+200 | -55~+200 | ||||||||

| RoSH | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |||||||||