Thermal Gel 2 Components TFG-series

Product Highlights

- 1:1 mix ratio

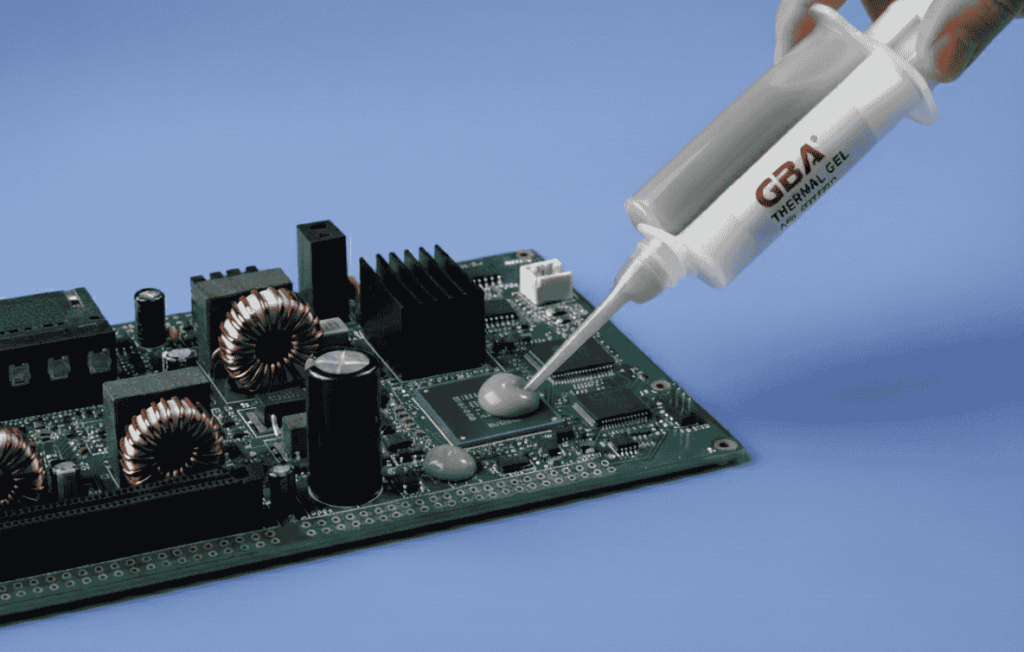

- Flowable, easy to operate

- Room temperature or elevated temperature curing

- Good insulation properties

- Low thermal resistance

- Easy to repair and rework

- RoHS Compliant

Applications

- Automotive Electronic Control Unit (ECU)

- Power and semiconductor equipment

- Memory and power modules

- Microprocessor and graphics processor

- Flat panel displays and consumer electronics

The TFG series is a soft, two-component thermally conductive gel material that offers exceptional thermal conductivity. This material can be cured at either room temperature or elevated temperatures, making it flexible for various application needs. Prior to curing, the gel retains excellent thixotropic properties, allowing for easy application. Once cured, it forms a soft, cure-in-place pad.

The TFG series is ideal for thermal management in applications involving low-pressure components, particularly when components share a common heat sink or enclosure with varying heights, or when a heat-generating component is applied to an uneven surface. The material effectively facilitates heat dissipation while softly and elastically absorbing height tolerances, providing protection to sensitive components.

Since the material is immobile before curing, it stays in place within the gap and will not flow out. After curing, it remains a low-modulus elastomer with outstanding electrical properties, water and moisture resistance, weather resistance, and stability across a wide temperature range. This combination of characteristics makes the TFG series highly effective in diverse and demanding thermal applications.

Our Thermal Gel 2 Components offer high-performance heat dissipation with a reliable room-temperature cure for complex assemblies. To guarantee long-term reliability in demanding environments, we ensure all formulations meet REACH and RoHS compliance standards. This ensures that our Thermal Gel 2 Components provide an environmentally safe, high-stability solution for high-power electronics and automotive modules.

SPECIFCATIONS TABLE

| Parameters | Units of Measure | TFG2055 | TFG1845LV | TFG2075 | TFG2640 | TFG3540 | TFG4845 | TFG6045 | |||||||||||

| Component | A | B | B | A | B | B | A | B | A | B | A | B | A | B | |||||

| Colour | Yellow | White | White | Yellow | Pink | White | Green | White | White | Blue | White | Grey | White | Pink | |||||

| Viscosity | cps | 250000 | 120000 | 250000 | 270000 | 150000 | 350000 | 500000 | |||||||||||

| Viscosity after mixing | cps | 250000 | 120000 | 250000 | 270000 | 150000 | 350000 | 500000 | |||||||||||

| Minimum Thickness | mm | 0.05 | 0.08 | 0.05 | 0.06 | 0.05 | 0.05 | 0.10 | |||||||||||

| Operating time @25°C | min | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |||||||||||

| Curing Time@100oC | min | 10 | 15 | 15 | 10 | 20 | 20 | 20 | |||||||||||

| Curing Time@25oC | h | 5 | 6 | 4 | 6 | 6 | 8 | 12 | |||||||||||

| After Curing | |||||||||||||||||||

| Hardness | Shore 00 | 55 | 45 | 75 | 40 | 40 | 45 | 45 | |||||||||||

| Thermal Conductivity | W/m·K | 2.0 | 1.8 | 2.0 | 2.6 | 3.5 | 4.8 | 6.0 | |||||||||||

| Thermal Resistance @50psi | oC·in²/W | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.07 | ≤0.06 | ≤0.04 | ≤0.035 | |||||||||||

| Dielectric Strength | kV/mm | ≥10 | ≥12 | ≥15 | ≥12 | ≥10 | ≥9 | ≥9 | |||||||||||

| Volume Resistivity | Ω·cm | ≥1.0×10¹³ | ≥1.0×10¹³ | ≥1.0×10¹³ | ≥1.0×10³ | ≥1.0×10¹² | ≥1.0×10¹² | ≥1.0×10¹² | |||||||||||

| Density | g/cm³ | 2.60 | 2.45 | 2.90 | 2.93 | 3.00 | 3.10 | 3.30 | |||||||||||

| Dielectric Constant | @1MHz | 6.5 | 6.5 | 6.8 | 6.5 | 7.0 | 8.5 | 7.5 | |||||||||||

| CTE (Coefficient of thermal expansion) | ppm/oC | 170 | 175 | 170 | 160 | 150 | 150 | 135 | |||||||||||

| Low Volatile Content (D4 – D20) | PPM | ≤100 | ≤100 | ≤100 | ≤100 | ≤50 | ≤30 | ≤30 | |||||||||||

| Flammability Rating | UL94 | V0 | V0 | V0 | V0 | V0 | V0 | V0 | |||||||||||

| Operating Temperature | oC | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+150 | |||||||||||

| RoHS | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||