FEF-series | All-direction Conductive Foam

Product Highlights

- Low Resistance & Good Conductivity: Offers superior electrical performance, providing better shielding and grounding.

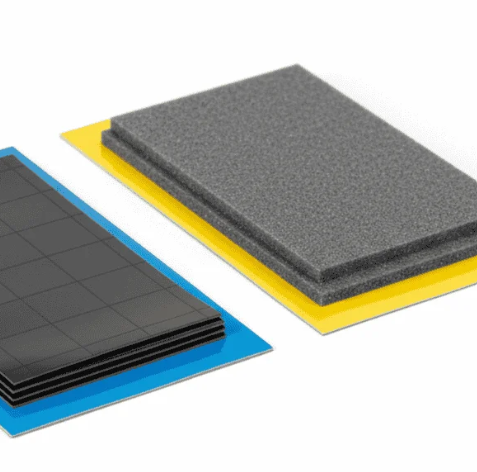

- Uniform Coating: Features a stable, consistent coating that ensures reliable electrical conductivity and enhanced corrosion resistance.

- Plating: The three-layer electroplating (nickel-copper-nickel) ensures both excellent conductivity and increased durability.

- Good Flexibility: The material is flexible, with excellent die-cutting properties for easy customization into various shapes.

- Excellent Elasticity & Shockproof Performance: Offers high elasticity, making it ideal for applications requiring shock absorption and protection.

- Thickness Options: Available in various thicknesses to meet a wide range of application requirements.

- Custom Adhesives: A range of adhesive types is available to suit different application needs.

- Flame Retardancy: Materials with a thickness of less than 3mm can be customized to meet UL 94-V0 flame retardancy grade, while materials thicker than 3mm can be customized to UL 94-HB grade.

Product Applications:

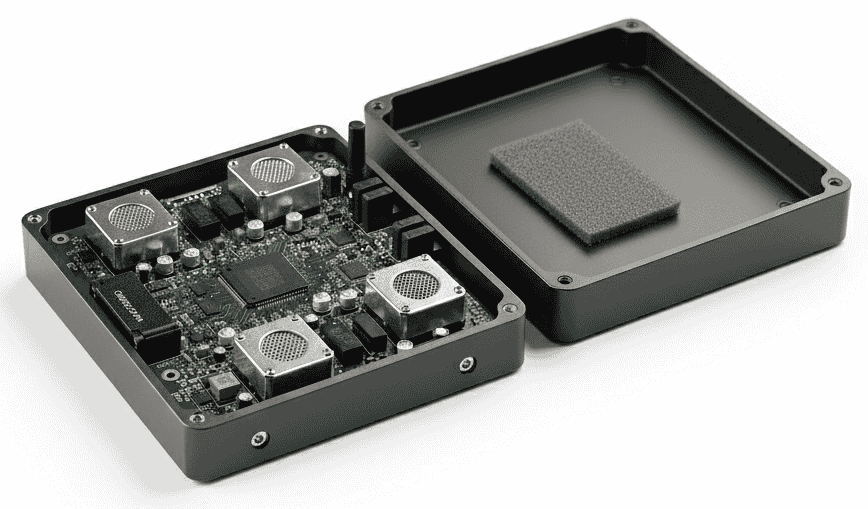

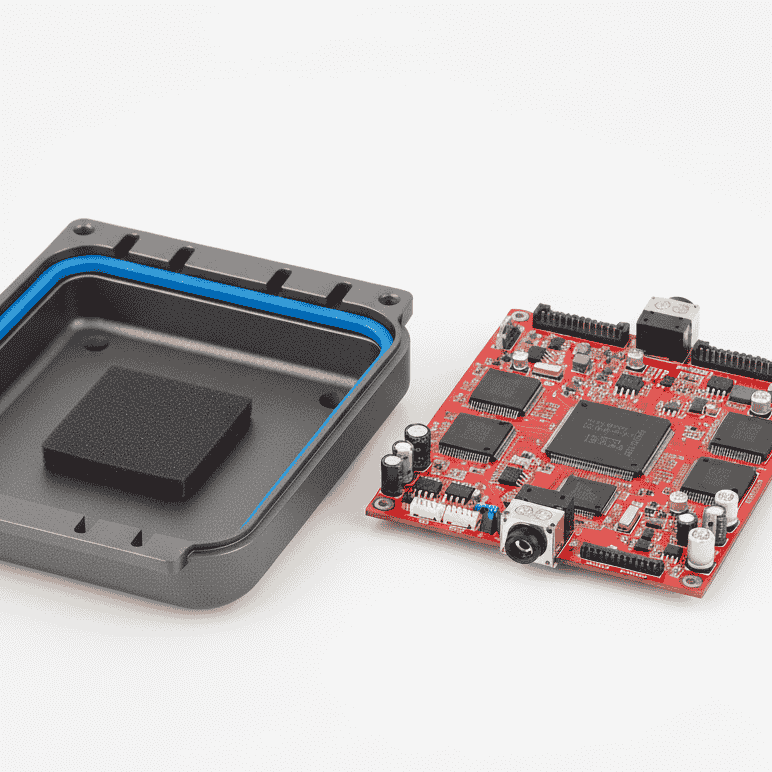

- Application environments requiring grounding for housing or cavities: Ideal for shielding and grounding applications in electronic devices.

- Mobile Phones and Laptops: Provides effective EMI shielding and grounding for portable electronics.

- Chassis and LCD Monitors: Ensures reliable EMI/RF shielding and grounding in computer chassis and display units.

- Chassis Cabinets Requiring Shielding: Protects sensitive components in industrial cabinets and enclosures from electromagnetic interference.

- Industrial Equipment and Mobile Communication Equipment: Offers durable shielding and grounding solutions for industrial machinery and communication devices in various environments.

Short Descriptions

The FEF series all-direction conductive sponge is a high-performance polyurethane composite foam known for its fine, uniform texture, softness, elasticity, and excellent anti-corrosion properties. This conductive material is created by electroplating a conductive metal layer onto the sponge, with the back of the sponge featuring a bonding conductive cloth that offers strong adhesiveness.

The FEF series sponge is unique in that it features a three-layer electroplating process—nickel-copper-nickel. This multi-layer plating not only ensures superior electrical conductivity but also enhances the material’s resistance to corrosion, thanks to the nickel plating on both sides. This combination of properties makes the FEF series an ideal solution for applications requiring both conductivity and durability in challenging environments.

SPECIFICATIONS TABLE

| Part Number | FEF1001 | Test Methods | |

|---|---|---|---|

| Parameters | Units of Measure | ||

| Color | – | Grey / Black | – |

| Thickness | mm | 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0 (tolerance above 0.7mm ± 30%, tolerance above 1.0mm ± 20%) | – |

| Peel Strength | Kgf/25mm | >0.8 @ stay for 30min, 1 in² | PSTC1017 |

| Tensile Strength | Kgf/25mm | >20 | – |

| Compression Set | % | <25 | ASTMD3574 |

| Operating Temperature | oC | -40~70 | – |

| Surface Resistivity (Fabric Side) | Ω/Sq | <0.12 | ASTMF390 |

| Z-axis Resistance | Ω | <0.12 | – |

| Shielding effectiveness | dB | >50@30MHz~18Ghz | MIL-DTL-83528C |

| Dangerous Goods Identification | – | RoHS compliance (2002/95/ec); Elements conforming to iec-61249-2-21 | – |

| Warranty Period | Month | 12 Month @ 23°C/60%R.H. | – |