NFP-series | Non-Silicone | 2.0 ~ 10.0 W/mK

Product Highlights

- Thermal conductivity 2.0 ~ 10.0 W/mK

- Silicone-free, for silicone sensitive applications

- Soft, good dielectric and thermal performance

- Flammability rating: UL94 V-0

- Thickness: 0.02 in (0.5mm) – 0.400 in (10.0mm) (Check specific product specification for thickness range)

Application

- Silicon-free environment and silicon-sensitive applications

- Aerospace

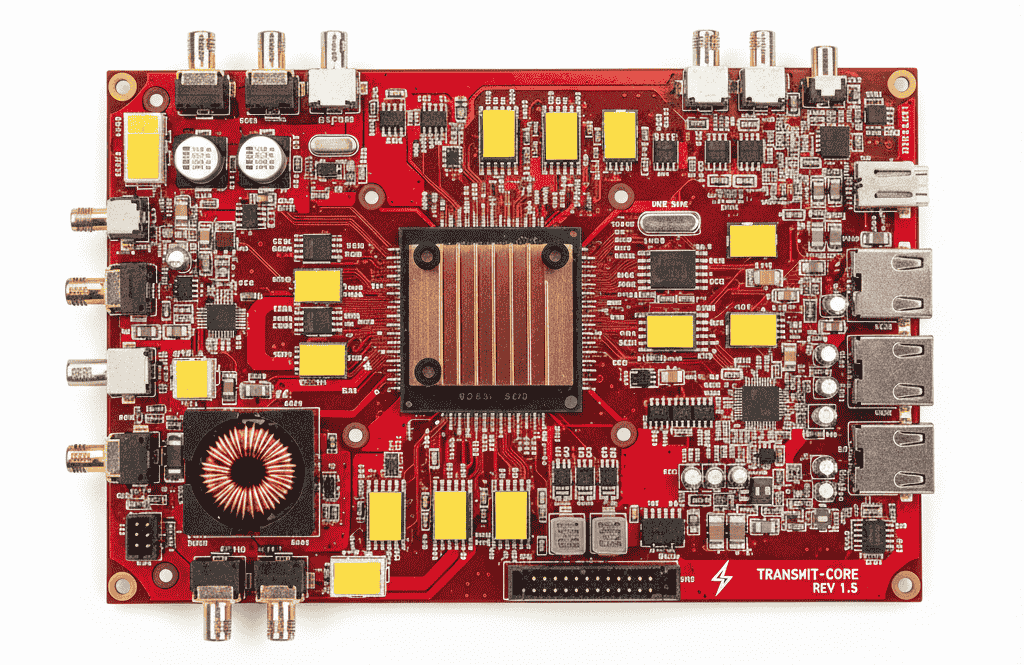

- Optical telecommunication

- Optical transmission equipment

- Projection equipment

- Lighting control equipment

The NFP series material is a high-performance, compressible, and silicone-free thermal pad specifically designed for silicone-sensitive applications. This material is ideal for environments where silicone presence is a concern, as it features low volatility, no silicone oil penetration, and prevents contamination of PCB circuits.

The NFP series is characterized by its soft texture, high compressibility, and excellent surface wetting properties, which lead to minimal thermal resistance between heat-generating components and heat sinks or housings. These qualities make it an excellent choice for applications where traditional thermal pads may be unsuitable due to their silicone content.

The material is naturally tacky on both sides, eliminating the need for additional adhesive coatings. Its inherent tackiness ensures the pad stays securely in place during assembly and operation, making the material easy to handle and facilitating the processing and assembly of heat-sensitive components.

SPECIFCATIONS TABLE

| Parameters | Unit of Measure | NFP2060 | NFP3060 | NFP4055 | NFP6075 | NFP8075 | NFPX040 |

| Colour | – | White | Light Blue | Blue Violet | Grey | Grey | Grey |

| Thickness | mm | 0.25~10 | 0.3~10 | 0.3~10 | 0.5~10 | 0.5~10 | 0.5~10 |

| Thermal Conductivity | W/m·K | 2 | 3 | 4 | 6 | 8 | 10 |

| Thermal Resistance @1mm,20psi | ℃·in²/W | 0.7 | 0.42 | 0.42 | 0.26 | 0.26 | 0.24 |

| ℃·cm²/W | 4.52 | 2.71 | 2.71 | 1.68 | 1.68 | 1.55 | |

| Hardness | Shore OO | 60 | 60 | 55 | 70 | 75 | 40 |

| Flammability Rating | V0 | V0 | V0 | V0 | V0 | V0 | |

| Breakdown Voltage | kV@1mm | >9.0 | >9 | >9 | >9 | >9 | >8 |

| Volume Resistivity | Ω ·cm | ≥1.0×1014 | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 |

| Density | g/cm³ | 2.4 | 2.8 | 1.6 | 3.32 | 3.35 | 3.55 |

| Tensile Strength | psi | 36 | 30 | 32 | 32 | 32 | 30 |

| Elongation | % | 55 | 60 | 50 | 50 | 50 | 40 |

| Compression Ratio (% at given pressure) | 10psi | 8 | 12 | 12 | 9 | 9 | 13 |

| 50psi | 20 | 42 | 35 | 28 | 28 | 35 | |

| 100psi | 35 | 56 | 62 | 45 | 45 | 52 | |

| Dielectric Constant | @1MHz | 6.5 | 5.5 | 3.5 | 6.5 | 6.5 | 6 |

| Operating Temperature | °C | -40~+110 | -40~+110 | -40~+110 | -40~+120 | -40~+120 | -40~+120 |

| RoHS | – | YES | YES | YES | YES | YES | YES |