TFP-series | 1.0 ~ 1.5 W/mK

Product Highlights

- Thermal conductivity 1.0 ~ 1.5 W/mK

- Self adhesion

- UL94 V-0 flame retardant grade

- Thickness range: 0.003 inch (0.07mm) -0.400 inch (10.0mm)

Application

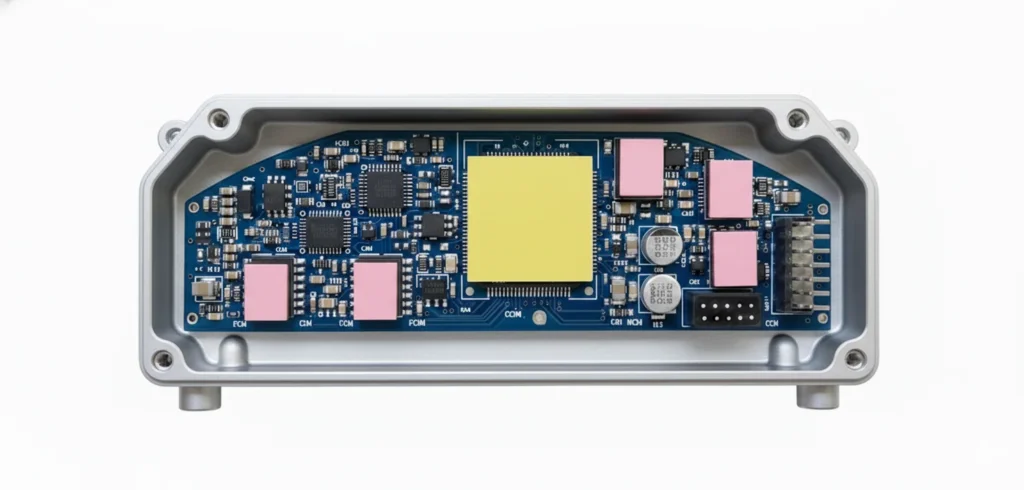

- Desktop computer, laptop and server

- LED lighting equipment

- Automotive electronics

- LCD and PDP flat display

- Automotive electrical modules, battery heat dissipation

TFP is a series of cost-effective thermal gasket material designed to offer both high performance and ease of use. With a specially optimized formula, it features low density while maintaining excellent thermal conductivity. The material’s natural tackiness ensures strong adhesion, which helps minimize interfacial thermal resistance for improved heat transfer.

This gap-filling gasket provides excellent heat conduction properties, making it an ideal choice for applications that require both performance and cost-efficiency. Its low density also aligns with the current trend in electronics toward reducing the form factor of devices.

To enhance usability and rework flexibility, a non-sticky “dry surface” is formed on one side of the gasket through a unique process. This allows the non-tacky side to be easily removed from chips and PCBs without damage. The naturally sticky side is typically applied to heat sinks, cold plates, or housings, ensuring secure attachment and efficient heat dissipation.

SPECIFICATIONS TABLE

| Part Numbers | TFP1025 | TFP1005EB | TFP1025EB | TFP1055 | TFP1255 | TFP1545 | TFP1525LV | FP1525PI | TFP1505EB | |

|---|---|---|---|---|---|---|---|---|---|---|

| Parameters | Unit of Measure | |||||||||

| Colour | – | White | White / Pink | White / Pink | Grey | Grey | Light Green | Light Green | Light Green | White / Brown |

| Thickness | mm | 0.5~10 | 0.5~10 | 0.5~10 | 0.07~10 | 0.07~10 | 0.07~10 | 0.07~10 | 0.15~10 | 0.5~10 |

| Thermal Conductivity | W/m·K | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 |

| Thermal Resistance @1mm,20psi | oC·in²/W | 1.16 | 1.01 | 1.16 | 1.25 | 1.15 | 0.98 | 0.90 | 0.96 | 0.95 |

| oC·cm²/W | 7.47 | 6.52 | 7.47 | 8.06 | 7.42 | 6.32 | 5.81 | 6.19 | 6.13 | |

| Hardness | Shore00 | 25 | 5 | 25 | 55 | 55 | 45 | 25 | 25 | 5 |

| Flammability Rating | – | V0 | V0 | V0 | V0 | V0 | V0 | V0 | V0 | V0 |

| Breakdown Voltage | kV(@1mm) | >10.0 | >12.0 | >12.0 | >12.0 | >10.0 | >10.0 | >10.0 | >12.0 | >12.0 |

| Volume Resistivity | Ω ·cm | ≥1.0×1012 | ≥1.0×1012 | ≥1.0×1012 | ≥1.0×1013 | ≥4.0×1013 | ≥5.0×1013 | ≥5.0×1013 | ≥5.0×1013 | ≥5.0×1013 |

| Density | g/cm | 1.60 | 1.60 | 1.60 | 1.3 | 1.75 | 1.85 | 1.85 | 1.85 | 1.85 |

| Tensile Strength | psi | 10 | 10 | 20 | 48 | 48 | 30 | 30 | ≥200 | ≥300 |

| Elongation | % | 35 | 40 | 50 | 55 | 60 | 55 | 55 | 15 | 15 |

Compression Ratio (%, at given pressure) | 10psi | 22 | 25 | 15 | 12 | 10 | 8 | 18 | 18 | 32 |

| 50psi | 54 | 60 | 40 | 40 | 42 | 38 | 46 | 46 | 58 | |

| 100psi | 75 | 86 | 58 | 58 | 58 | 55 | 62 | 62 | 82 | |

| Dielectric Constant | @1MHz | 5.5 | 5.5 | 5.5 | 4.5 | 5.5 | 6.2 | 6.2 | 6.2 | 6.2 |

| Low Volatile Content (D4~D20) | ppm | – | – | – | – | – | – | – | – | – |

| TML(CVCM) | % | ≤0.35(0.12) | ≤0.35(0.12) | ≤0.35(0.12) | ≤0.55(0.25) | ≤0.35(0.10) | ≤0.55(0.10) | ≤0.55(0.10) | ≤0.55(0.10) | ≤0.55(0.10) |

| Operating Temperature | oC | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 | -60~+200 |

| RoHS | YES | YES | YES | YES | YES | YES | YES | YES | YES |