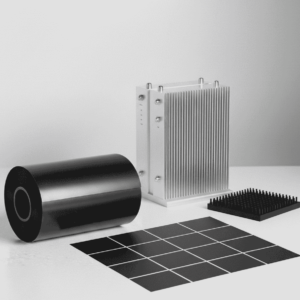

Choosing the right thermal interface materials is vital for cooling electronics. Using the correct materials ensures better performance and longer hardware life.

EV | Telecom | New Energy | Data Centre | Robotics

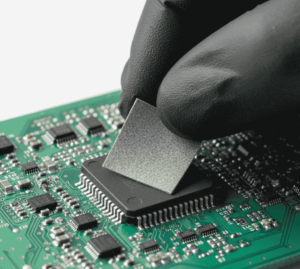

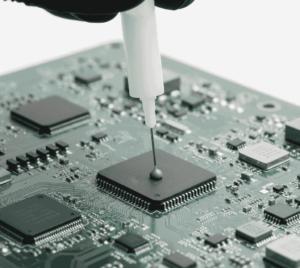

Choosing the right thermal interface materials is vital for cooling electronics. Categorizing these materials by conductivity and thickness helps eliminate air gaps and prevent overheating. Using the correct thermal interface materials ensures better performance and longer hardware life.

Key Categories Thermal Interface Materials

To choose the best solution, we categorize pads into three primary groups:

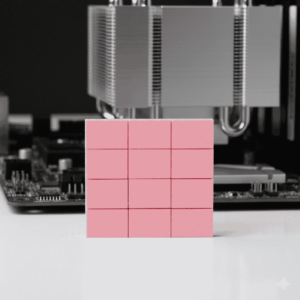

- Performance Grade: These TIM offer high conductivity (often above $10 W/mk$) and are designed for high-end GPUs and CPUs where heat density is extreme.

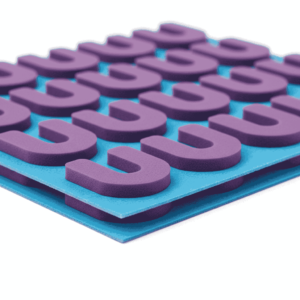

- Gap Fillers: These are softer thermal interface materials with high compressibility. They are ideal for uneven surfaces or where multiple components of varying heights need to touch the same heat sink.

- Industrial Silicons: Standard TIM used in everyday power supplies and LED drivers, focusing on long-term stability and cost-effectiveness.

Why Categorization Thermal Interface Materials

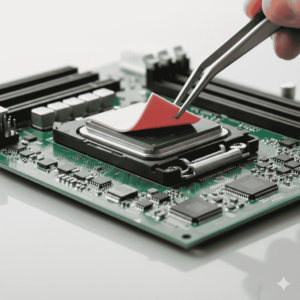

Properly identifying TIM prevents common assembly errors. If a material is too hard, it can put mechanical stress on the PCB. If it is too thin, it won’t bridge the gap, leading to component failure. By organizing our inventory into clear categories, we ensure that every application—from consumer laptops to industrial servers—receives the exact thermal management it requires.

Furthermore, the longevity of TIM depends on their chemical makeup. Silicone-based options offer flexibility, while non-silicone versions prevent “bleeding” or oil leakage in sensitive optical equipment. Understanding these nuances is the key to professional-grade thermal management.

For the best results, compare our TIM specs against industry standards like ASTM D5470 to verify high-performance heat transfer.