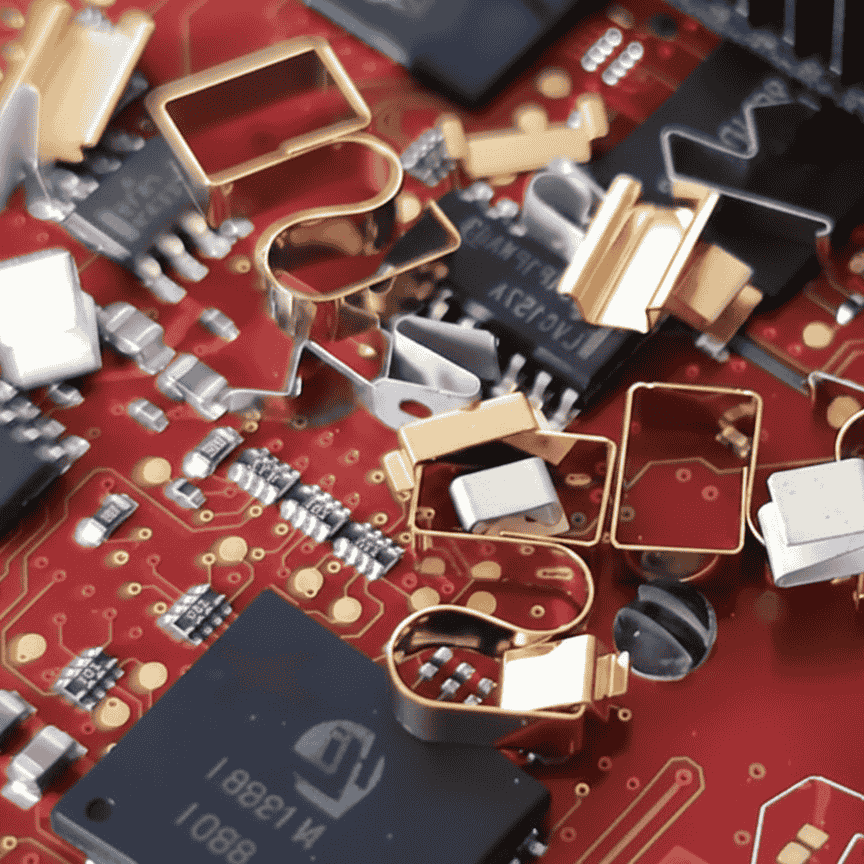

Grounding Contact Springs

Common Applications

- Smartphones and Tablets: Connecting the antenna to the logic board or grounding the camera module.

- Automotive Electronics: Ensuring signal integrity in ADAS sensors and infotainment systems.

- Laptops: Providing grounding between the keyboard frame and the chassis.

- EMI Shield: simple and easy installation for many telecom devices

- Ground: providing simple and straight forward grounding paths between PCB and enclosures

for specs and details, please click button on right

DESIGN CONSIDERATIONS

- Produc assembly method. (soldering, screw, clip, etc.)

- Product operation height and part height. (involving material elasticity and usage requirements, focusing on evaluating failure risk)

- Work environment and corrosion resistance. (Selection of material and plating)

- SMT automation requirements. (packaging selection and T&R design)

- Working current and voltage. (considering the cross-section area and material)

- Product structural space. (product structure selection )

- Product reliability testing. (such as compression frequency and compression reflection requirements)

CHARACTERISTICS OF BERYLLIUM COPPER

- Beryllium copper is an alloy with high conductivity.

- Due to its high heat transfer and conductivity, beryllium copper can be used in applications such as heat dissipation and signal transmission.

- Compared to traditional alloys, beryllium copper has lower density and higher strength.

- The excellent processability of beryllium copper makes it suitable for various types of products.

SMD CONTACT FEATURES

- High reliability, long service life, and can withstand high temperature and humidity environments.

- Automated production, significantly reducing assembly costs.

- Low impedance, achieving good EMI & ESD shielding effect.

- Due to its excellent elasticity, it can be designed for use in various lightweight, small-size, or complex structures.

Our Grounding Contact Springs are precision-engineered from high-conductivity alloys like beryllium copper to ensure consistent spring force and low contact resistance over thousands of cycles. To guarantee that these components meet global safety and environmental requirements for the electronics industry, all our spring solutions are strictly REACH and RoHS compliant. This ensures that every Grounding Contact Spring provides a safe, lead-free, and high-performance grounding solution for smartphones, automotive sensors, and telecommunications hardware.