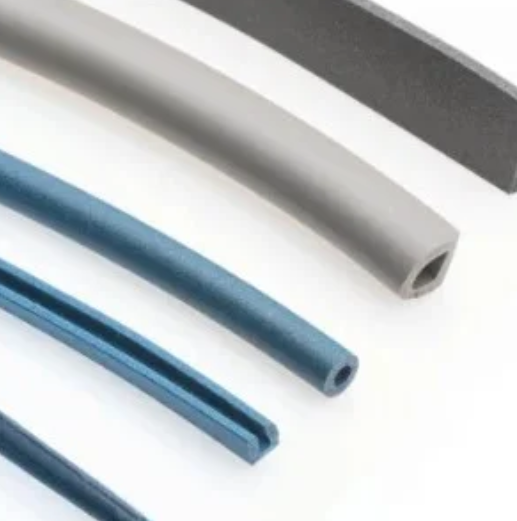

EC-series | EMI Electrically Conductive Elastomer

Product Highlights of EMI Electrically Conductive Elastomer

- Ultra-low resistance and excellent shielding performance are

achieved after proper compression - Excellent environmental sealing, up to Ip68

- Excellent mechanical properties, softness, and resilience

- Easy customization, fast samples in sheet, strip, customized

shape, by die cutting, molding, extrusion

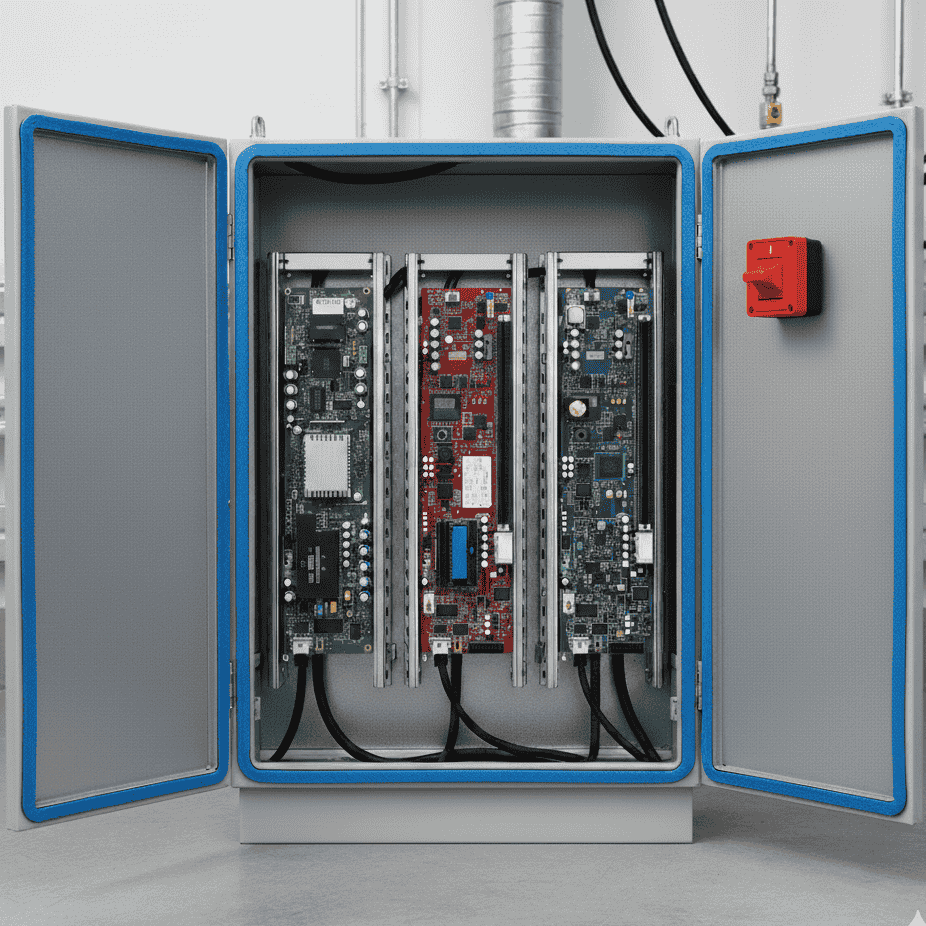

Product application of EMI Electrically Conductive Elastomer

- Communication equipment

- Automotive electronics

- Medical instrument

- IO dust control

- Server

EMI Electrically Conductive Elastomer material selection

The material selection of EMI Electrically Conductive Elastomer is based on the key factors of performance, cost, and the specific requirements of the application, especially in areas like aerospace, industrial, and commercial electronics. Here’s a breakdown of the materials mentioned, their properties, and applications:

Characteristics and features of EMI Electrically Conductive Elastomer

1. GBT-eSEAL EC2320 (Ag/Al, Fluorosilicone)

- Key Features:

- Excellent shielding: Protects against electromagnetic interference (EMI) and radio frequency interference (RFI).

- Corrosion resistance: Ensures longevity and durability in harsh environments, particularly in aerospace applications.

- Fluorosilicone: Offers superior thermal stability and resistance to fuel, oils, and chemicals.

- Applications: This material is ideal for aerospace applications where reliability and service life are critical. The combination of shielding and corrosion resistance enhances performance in extreme conditions.

2. eSEAL EC2310 (Ag/Al, Silicone) EMI Electrically Conductive Elastomer

- Key Features:

- High conductivity: Provides effective shielding and grounding.

- Silicone base: Known for flexibility, thermal stability, and resistance to high temperatures.

- Applications: Suitable for industrial-grade applications where a balance of shielding and grounding is required. The high conductivity makes it ideal for shielding sensitive equipment.

3. eSEAL EC2410 (Ag/G, Silicone)

- Key Features:

- Silver-Gold (Ag/G) combination: Enhances conductivity for superior shielding.

- Silicone: Maintains flexibility and stability under varying environmental conditions.

- Applications: This material is suitable for higher-level shielding requirements in industrial applications, especially where more robust electrical protection is necessary.

4. eSEAL EC2510 (Ag/Cu, Silicone)

- Key Features:

- Silver-Copper (Ag/Cu) composition: Offers a good balance of electrical conductivity and cost-effectiveness.

- Silicone: As with other silicone-based materials, it offers durability, thermal stability, and flexibility.

- Applications: Ideal for shielding applications where both high conductivity and good grounding are needed.

5. EC2110 (Nickel-Carbon Filled Conductive Rubber)

- Key Features:

- Cost-effective: Provides an economical solution without sacrificing basic conductivity.

- Low weight: Ideal for applications where weight is a critical factor.

- Nickel-carbon fill: Provides conductive properties with lower overall cost compared to metals.

- Applications: This material is well-suited for commercial and general consumer electronics applications, where cost and weight are important considerations.

Manufacturing Capabilities and Customization of EMI Electrically Conductive Elastomer

GBA offers versatile manufacturing capabilities such as:

- Extrusion: For continuous production of profiles, suitable for large quantities of custom shapes.

- Molding: Ideal for creating specific designs in high volumes, including high-precision components.

- Die-cutting: Allows for the production of precise parts, typically for gaskets, seals, and other flat components.

- Overmolding with Metal Parts: This allows combining elastomeric materials with metal inserts, providing a dual function for grounding and shielding, improving mechanical performance, and ensuring strong bonding between metal and rubber parts.

Thee production process of are adaptable to both mass production and small batch orders for engineering design variations, offering customers flexibility in manufacturing based on their specific needs, whether they are optimizing for performance or cost.

In summary, the selection of materials such as the EC2320 for aerospace or the EC2110 for commercial applications is driven by the balance between technical performance (e.g., shielding, conductivity, corrosion resistance) and economic considerations (e.g., cost, weight). The versatility of GBA’s manufacturing processes ensures that these materials can be customized and produced to meet both large-scale and niche application needs.

Our EMI Electrically Conductive Elastomer provides a high-performance solution for simultaneous environmental sealing and electromagnetic interference shielding. To ensure these materials meet the rigorous requirements of military and aerospace applications, we align our testing with the MIL-DTL-83528 standard. This ensures that every EMI Electrically Conductive Elastomer provides the precise shielding effectiveness and material durability needed for high-frequency telecommunications and defense electronics.

SPECIFICATIONS TABLE

To see Dimensions and Cross-Section profiles, please click button on right

| EC Material # | EC2010 | EC2110 | EC2210 | EC2310 | EC2320 | EC2410 | EC2510 | EC2710 | Test Method | |

| Substrate | Silicone | Silicone | Silicone | Silicone | Fluoro-silicone | Silicone | Silicone | Silicone | N/A | |

| Conductive Particle | C | Ni/C | Ni/Al | Ag/Al | Ag/Al | Ag/G | Ag/Cu | Ag | N/A | |

| Color | Black | Black | Gray | Taupe | Blue | Taupe | Taupe | Taupe | Visual | |

| Density (g/cm³) | 1.2 | 1.9 | 2.4 | 2.2 | 2.2 | 2.0 | 3.5 | 4.3 | ASTM D792 | |

| Volume Resistivity | 3.0 | 0.1 | 0.1 | 0.008 | 0.012 | 0.006 | 0.004 | 0.002 | MIL-DTL-83528C | |

| Volume Resistivity (Shore A) | 70 | 65 | 75 | 65 | 60 | 65 | 60 | 70 | ASTM D2240 | |

| Tensile Strength (PSI) | 700 | 200 | 200 | 180 | 120 | 200 | 200 | 150 | ASTM D412 | |

| Elongation (%) | 200 | 150 | 150 | 150 | 120 | 150 | 150 | 100 | ASTM D412 | |

| Tear Strength (PPI) | 80 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ASTM D624 | |

| Shielding Effectiveness (dB) | 500M | 60 | 100 | 110 | 110 | 105 | 100 | 120 | 130 | MIL-DTL-83528C |

| 2G | 60 | 100 | 105 | 105 | 100 | 100 | 120 | 130 | ||

| 10G | 60 | 100 | 100 | 100 | 100 | 100 | 120 | 130 | ||

| Operating Temperature (oC) | -55~170 | -55~170 | -55~170 | -55~170 | -55~170 | -55~170 | -55~170 | -55~170 | ASTM D1329 | |