FlexFOAM FEF All-direction Conductive Foam

Product Application

- Application environment where the housing or cavity needs to be grounded

- Mobile phone, laptop

- Chassis, LCD monitor

- Chassis cabinets requiring shielding

- Industrial equipment, mobile communication equipment, etc.

Product Features

- Low resistance, good conductivity, providing better shielding performance

- Uniform coating, stable electrical conductivity and corrosion resistance

- Plating

- Good flexibility, good die-cutting properties, customized die-cutting

- Various shapes

- Good elasticity and shockproof performance

- Thickness is optional for a wide range of applications

- For materials with a thickness of less than 3mm, the flame retardancy grade

UL 94-V0 can be customized; for materials larger than 3mm, the flame

retardancy grade UL 94-HB level can be customized - Various types of adhesives are available

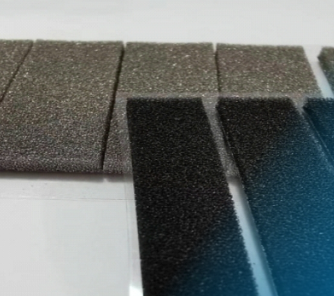

FEF series all-direction conductive sponge is a polyurethane composite foam with fine, uniform, soft, elastic and anti-corrosion properties. This all-directional conductive material is formed by electroplating a conductive metal layer on the basis of the sponge, and the back of the conductive sponge is a bonding conductive cloth with good adhesiveness. GoodBon Tech’s sponge has 3 layers of electroplating layers, which are nickel-copper-nickel, which not only ensures good electrical conductivity, but also increases the anti-corrosion performance of the material by the nickel plating on both sides.

Specifications Table

| Item | Unit | Parameter | Test Method |

| Color | – | Grey / Black | – |

| Thickness | mm | 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0 (tolerance above 0.7mm ± 30%, tolerance above 1.0mm ± 20%) | – |

| Peel Strength | Kgf/25mm | >0.8 @ stay for 30min, 1 in² | PSTC1017 |

| Tensile Strength | Kgf/25mm | >20 | – |

| Compression Set | % | <25 | ASTMD3574 |

| Operating Temperature | ℃ | -40~70 | – |

| Surface Resistivity (Fabric Side) | Ω/Sq | <0.12 | ASTMF390 |

| Z-axis Resistance | Ω | <0.12 | – |

| Shielding Performance | dB | >50@30MHz~18Ghz | MIL-DTL-83528C |

| Dangerous Goods Identification | – | RoHS compliance (2002/95/ec); Elements conforming to iec-61249-2-21 | – |

| Warranty Period | Month | 12 Month @ 23°C/60%R.H. |