OEF-series | Conductive Fabric Over Foam Gasket

Product Highlights

- shielding effectiveness up to 90 dB

- Low compression

- Good cost performance ratio

- Simple and diverse installation methods

- Products comply with ROHS, Reach, UL94-V0 and other standards

Applications of OEF Conductive Fabric Over Foam Gaskets:

- General Equipment: Provides effective EMI/RF shielding for a wide range of electronic devices.

- Household Appliances: Ensures protection against electromagnetic interference in home electronics and appliances.

- Electrostatic Discharge (ESD) Applications: Helps prevent damage to sensitive components by shielding against electrostatic discharge.

- Industrial Equipment, Laptops, and Tablets: Offers reliable EMI shielding for industrial machinery and portable electronics, enhancing their performance and reliability.

Descriptions:

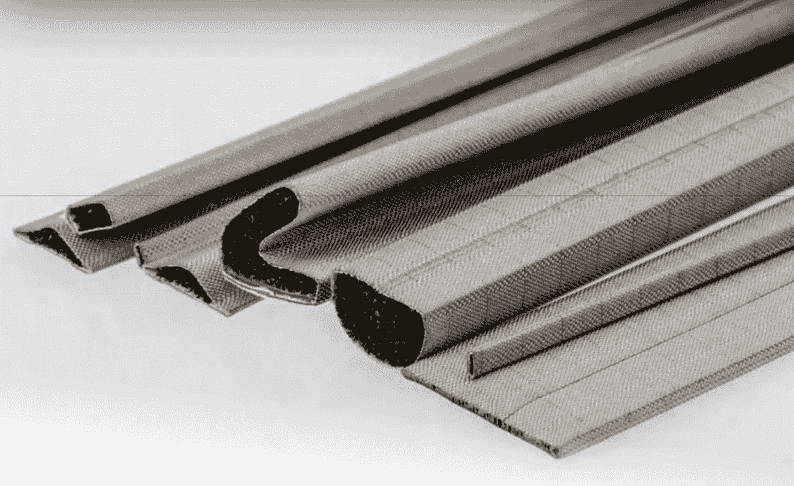

OEF Conductive Fabric Over Foam is an EMI shielding material that combines a highly elastic sponge core with conductive fabric or metallic foil. This material offers exceptional characteristics, including low compression force, high compression ratio, excellent shielding performance, and flexible installation methods. It provides a lightweight, flexible solution for shielding EMI/RF interference in equipment.

The OEF series is also easily die-cut, enabling cost-effective custom shielding structures tailored for various I/O ports. Our engineers can assist customers in selecting the appropriate materials and customizing the die-cut design to meet specific application requirements, ensuring the best solution for diverse environmental conditions.

SPECIFICATIONS TABLE

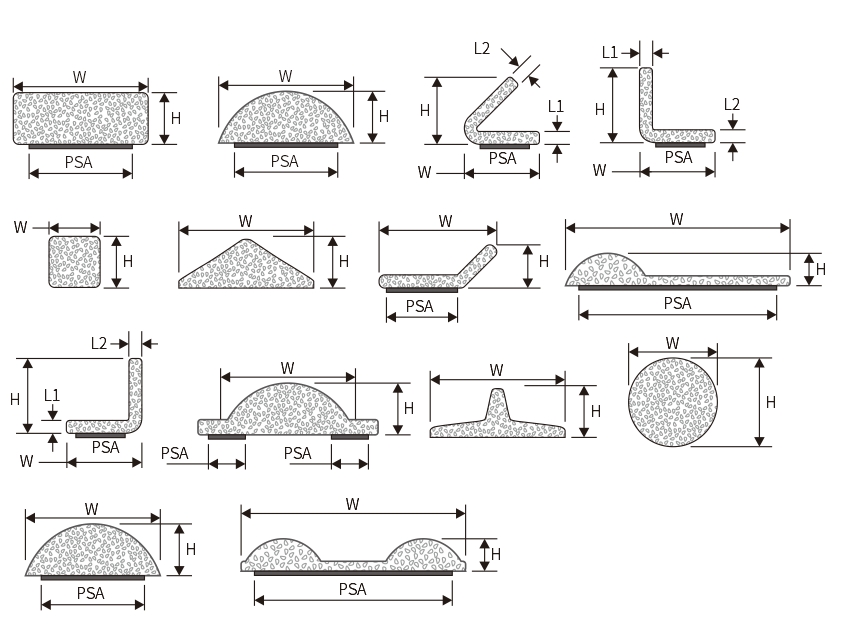

To see Dimensions and Cross-Section Profiles, please click button on right

| Item | Ni/Cu Polyester Taffeta | Ni/Cu Polyester Ripstop | Ni/Cu Polyester Mesh | Ni/Cu Polyester Nonwoven | Graphite Film | Nickel Plated PI | Tin Plated PI | Anti-Oxidant Al Foil | Test Method |

| Color | Grey/Black | Grey | Grey | Golden | Silver | Silver | Visual | ||

| Substrate | Fabric | Fabric Mesh | Non-Woven | Graphite Film | PI Film | PI Film | NA | ||

| Surface Resistivity (Ω/sq) | <0.07 | <0.07 | <0.07 | NA | <0.02 | <0.05 | ASTMF390 | ||

| Shielding Effectiveness (dB) | 70 | 40 | 80 | NA | 90 | 80 | MIL-G-83528C | ||

| Flammability | HB-V0 | HB | HB | V0 | V0 | V0 | UL-94 | ||

| Operating Temperature (°C) | -40~+120 | -40~+120 | -40~+120 | -40~+200 | -40~+250 | -40~+150 | Thermometer | ||

| Tensile Strength (Ib/in) | 70~80 | 40~50 | 80~100 | 50~60 | 50~60 | 80~100 | ASTM5035 | ||

| Air Flow (ft³/min/ft²) | 60 | NA | 500 | 500 | 650 | 650 | – | ||

| Advantages | Flame Retardant, High Shear Resistant | Low Cost | Flame Retardant High Shear Resistant | Heat Dissipation | High Temperature, Solderable | High Temperature Strong Structure | – | ||

| Suggested Application | I/O or Complex Shape Profiles | I/O | I/O or Complex S hape Profiles | Special Application | SMD | Special Application | – | ||

Available Cross Sectional Profiles